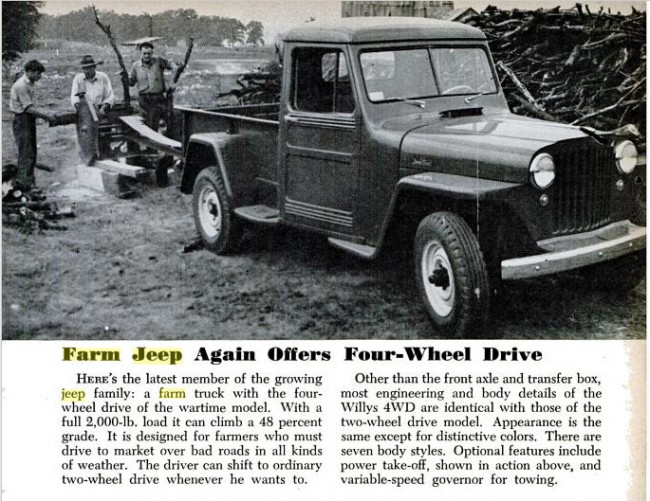

The September 1947 issue of Popular Science has this cool picture of a truck powering a saw.

One comment on “Photo of Truck Powering a PTO Saw”

Leave a Reply

emailNeed to contact me and don't have my email? Click on email button.

Welcome to eWillys.com, a website for vintage jeep enthusiasts. I update this website nearly every day with jeep deals, jeep history, interesting reader projects, jeep related info, and more.

These quick searches can help you find things on eBay. People list in the wrong categories all the time, so don't be surprised to see brochures in the parts area for example.

The links to posts below show jeeps grouped by models, condition, and other ways. Some of these jeeps are for sale and others have been sold. If you are unsure whether a vehicle is still for sale or not, email me at d [at] ewillys.com for more info.

There are plenty of interesting, unusual, historic and surprising stories related to Jeeps and their owners. In addition, some of these features have nothing to do with jeeps. This link will display all featured stories starting from the latest.

Looking for parts and not sure where to go? There are a variety of large and small new and used parts sellers both online and offline.

Importantly, the allure of buying a project jeep can be romantic. The reality of restoring a jeep can be quite different, expensive and overwhelming without the right tools and resources. So, tread carefully when purchasing a "project". If you have any concerns about buying a vintage jeep, or run across a scam, feel free to contact me for help, comments or concerns .

The September 1947 issue of Popular Science has this cool picture of a truck powering a saw.

Copyright © 2008-2017 eWillys. All rights reserved.

Powered by Wordpress, theme based on the Simple Grid Theme.

Some of the Daimler Chrysler, Inc., trademarks including Jeep®.

eWillys is hosted by the McDonagh Brothers

It always bothers me to see the straight belts without a twist. Somehow I remember from my Dad this was a safety factor but according to this it was to help even wear on the belt. Of course the twist would reverse direction also?

http://en.wikipedia.org/wiki/Belt_(mechanical)

Flat belts

The drive belt: used to transfer power from the engine’s flywheel. Here shown driving a threshing machine.

Flat belts were used early in line shafting to transmit power in factories.[2] They were also used in countless farming, mining, and logging applications, such as bucksaws, sawmills, threshers, silo blowers, conveyors for filling corn cribs or haylofts, balers, water pumps (for wells, mines, or swampy farm fields), and electrical generators. The flat belt is a simple system of power transmission that was well suited for its day. It delivered high power for high speeds (500 hp for 10,000 ft/min), in cases of wide belts and large pulleys. These drives are bulky, requiring high tension leading to high loads, so vee belts have mainly replaced the flat-belts except when high speed is needed over power. The Industrial Revolution soon demanded more from the system, and flat belt pulleys needed to be carefully aligned to prevent the belt from slipping off. Because flat belts tend to climb towards the higher side of the pulley, pulleys were made with a slightly convex or “crowned” surface (rather than flat) to keep the belts centered. Flat belts also tend to slip on the pulley face when heavy loads are applied and many proprietary dressings were available that could be applied to the belts to increase friction, and so power transmission. Grip was better if the belt was assembled with the hair (i.e. outer) side of the leather against the pulley although belts were also often given a half-twist before joining the ends (forming a Möbius strip), so that wear was evenly distributed on both sides of the belt (DB). Belts were joined by lacing the ends together with leather thonging,[3][4] or later by steel comb fasteners.[5] A good modern use for a flat belt is with smaller pulleys and large central distances. They can connect inside and outside pulleys, and can come in both endless and jointed construction.