Colin bought a Hickey aluminum cylinder head to modify his 1960 Surrey, but ran into some problems with it. Below he describes the changes he made, the problems he encountered, and his current solution. Thanks for sharing Colin!

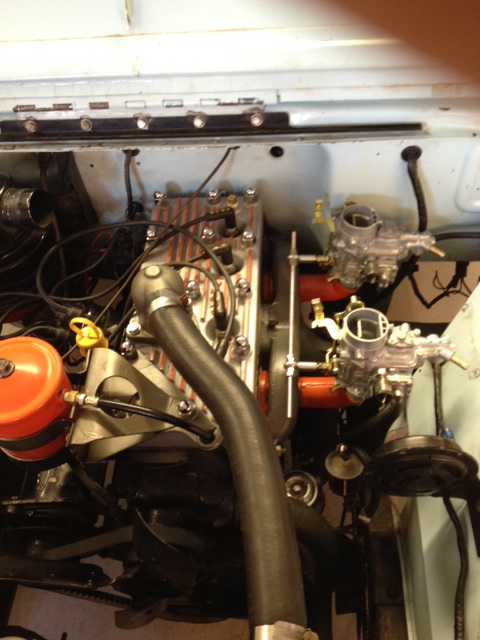

I started a hop-up project on our Surrey that involved the installation of a 1950s Nick Hickey aluminum cylinder head for the L-134. That morphed into the fabrication of a dual carb setup using two intake manifolds with a balance tube an F Head exhaust manifold that a very good friend, Steve Mason, and I fabricated out of an old manifold supplied by Jim Sullivan.

The first issue was the two new Weber carbs. They were supposed to be synchronized and jetted the sam, but weren’t. That led to the rear carb dumping extra fuel into #s 3&4, resulting in a blown head gasket which dumped coolant into those cylinders.

Hickey head top and bottom.

Took it all apart, rejetted the carbs and had the head resurfaced. I finished buttoning everything up and fired it up. adjusted the carbs slightly, running smooth, then noticed coolant in the #2 spark plug recess. Shut it off, pulled all plugs, could see coolant in #2, and steam coming from what must be a crack in the threads.

When I had the engine running previously I did not have water pooling in the plug basins. Upon looking at the plugs, the electrodes indicated the possibility of them coming in contact with the valves. Took a very hi intensity flashlight and looked into the cylinders and at least two of the valves I saw the imprint of the electrode on the valves.

So my theory is this:

I had the head resurfaced and in that process, the machine shop used an epoxy to smooth the surface indentations( corrosion?), and then did the resurface. The plugs I had used were nearly new from the original head. Those electrodes did not extend into the combustion chamber. The machine shop( guys who do a lot of work on Ford V8s with aluminum heads told me to get plugs with a slightly longer shank for better combustion. So I did. Only a small imperceptible difference in length.

What I think happened is the extra length of the plugs, coupled with the resurfacing of the head resulted in contact with the plugs and caused a small crack in #2 plug hole. Two head gaskets might have alleviated he problem, but maybe not. From what I have learned, huge advances in metallurgy with aluminum since the 50s and 60s resulted in much better aftermarket heads for the old flathead Fords. Since my Hickey head was made in the 50s, it is now over 60 years old.

So I removed the Hickey head and re-installed the original head. Fortunately I had an extra new head gasket. The new plugs don’t appear to extend any deeper into the combustion chamber than the old plugs, leading me to think the difference might be in the aluminum casting itself.

I am going to use the dual carb setup unless another problem crops up and then I will revert back to the single carb. With the dual carbs, I can still use the F-head exhaust manifold, as it has better flow and no heat riser plumbing.

My buddy Steve Mason suggested a sodium silicate repair that might work, but you have to flush the entire cooling system of all antifreeze several times and even then it is a 50/50 proposition for success. So I went back to the original head.

After attaching the original head. a buddy with some knowledge of Weber carbs and an engine analyzer got everything in working order. He even did some modifications to fuel lines and linkage to get things right.

The buddy I mentioned earlier worked on it yesterday and got it running fine, the carbs are tuned by ear for the most part.

On the way home from his house I had a minor setback, the nut and lock tab that holds the linkage on the #1 carb came off and left me running on two cylinders!

JOHNNY POPPER!!!

Got it home and went back looking for the linkage arm that fell off. Knew about where it started running rough, so walked that vicinity, both sides of the street for about half a mile and actually found the linkage arm, but not the nut or lock tab.

My buddy had a nut and tab so we are back in business. It does have a low speed miss just off idle probably due to #2 intake not seating properly. A valve job in the not too distant future

Thanks Dave, for putting this out! The engine, aside from the low speed miss just off idle, runs great and the dual carbs make a big difference in acceleration, even with the low compression original head. I do have a couple of leads on aluminum head repair and for custom copper head gaskets. When I do the valve job, I will try to use the Hickey Head again, since it is just too damn cool looking!

Lesson learned; leave well enough alone. For future reference, keeping those carbs in sync will be no picnic, wait and see. I know, everybody is saying, what does he know? Time will tell. These aluminum heads were disaster form day one, even back when they were new. Aluminum may not rust but it does break down over time. Surprised anybody would bother wasting time & money like this. With all due respect of course.

You guys should have been at the spring reunion where the guy had a custom F head cranking out 125 Horse. Now that was some engine work!

Cool article. Thanks for sharing it.

With all due respect, Mike, if it weren’t for challenges, we would lead rather boring lives. Taking a Jeep engine and doing some minor modifications to it for looks and even a bit of extra performance is stuff that Jeep guys have been doing since WWII when GI’s were taking Ford flathead engines out of military vehicles and putting them in Jeeps. If guys like Edmunds, Burns, Edelbrock, Hickey and Chucua hadn’t experimented with some of this stuff, Jeep performance past the mid 1940s may not have happened.

If the dual carb setup doesn’t work out well, I can change the whole thing back to original in a couple of hours. Yeah, I spent some money on the project, and a lot of time, but banging heads with a couple of my friends over how to make this work was what a bunch of retired old farts like me find fun to do.

Make no mistake, I like originality, my 60 Corvette with factory dual carbs is restored very close to NCRS standards. The CJ3A I sold recently was one we restored to original with the exception of a 12 volt system. Working together, my buddy Jim Sullivan and a couple of friends did body off back to original restorations on his 49 Jeepster and his 61 DJ3A Dispatcher. My VJ2 Jeepster sports a 231 BUick V6 coupled to a Muncie close ratio 4 speed, a 69 Ford Mustang rear end and up front, Mustang II front suspension. Yeah it’s not original under the body, but the exterior looks like the day it rolled out of Toledo. And it will go faster than 55 safely.

Why would anyone spend the time and money to do that? It beats hell out of sitting in a bar, smoking cigarettes or in front of a TV all the time. My car hobby gave me the ability to get away from the stress of being a cop for over half my life. My wife always knew where she could find me.

Sorry guys, for letting me expound at length on Mike’s comments. Mike, I do appreciate what you said, and if the things go down hill, I will be sure and let you know!

Colin, a bit off-topic, but still Willys-related – do you have a build thread or pictures anywhere of your VJ2 Jeepster build? That sounds like exactly what my Dad would like. He’s looking for his next project after selling his stock ’43 MB and would like more of a driver.

And I couldn’t agree with you more. I tell my wife that I could be at a bar/club/whatever, but inside I’m home with Willys on the mind.

Colin, I respect your opinion, I’ve been blessed in many ways, I don’t drink nor smoke, never been a drugie and never married. I guess you guys have more time and money then I do, I just can’t afford to throw either one away. I’m 66 and I still have to work to make like worthwhile. Coming from NJ, we always tell it like it is. I can remember reading about these Willys souped up aluminum heads back when I was a kid in the 50’s. Even then Popular mechanics and such as Mechanix illustrated didn’t recommend it. I think Uncle Tom McCahill had some negative comments about it, and that’s my point. Remember the Chevy Vega? another aluminium disaster.

A guy walked by my Hershey Booth with a sign on his back “WANTED WHIPPET PARTS”. I yelled for him to stop, as most of you know our Go Devil L-134 started life in a late 20’s Whippet with Barney Roos working it over for the MB Willys.

A fun conversation resulted as his 1928-29 Whippet Model 96A has an Alexander Aristocrat Over Head Valve Conversion on it, probably taken from a early 30’s Model 77 Willys, which he reported as working well. Somewhere in my stash I have the original sales sheet for this conversion. Stay Tuned (A Teaser) and in the same folder is an unpublished Willys 77 Racer article I wrote in the early 90’s for Willys World, club magazine for the defunct Willys Club, which we lost when the Treasurer ran off with the treasury. Maybe Dave will publish it, even though it is pre Jeep stuff, and there has been no group dedicated to the Model 77 since, that I knew of. (Maybe an “Aftermarket Willys Goodies”section)

To Dan first, then back to Mike:

Dan, I don’t have a build thread on our Jeepster, but I can give you a good rundown on what we did to make the modifications. Give me a call at 602-810-1495 and I can give you some ideas.

Mike, I know that aluminum heads and other items from the 50s haven’t fared too well, but the survivors are rare and I guess that is the draw. I’m in my early 70s, my wife and I both worked raised 4 kids and I usually had off duty jobs, sometimes 2 or 3. So it’s not like we have a lot of money, but we are doing OK with our retirement funds. Once the kids were off on their own things were easier and we had some extra money to spend on hobby stuff. I got the Jeepster nearly 40 years ago and worked on it as money was available, and have done nearly all the work on it myself and with the help of friends. I bought the Corvette worth the money 22 years ago and spent nearly every weekend for 4 years restoring it. Parts were bought as the money was available. Fixed up cars for the boys, then redid the Jeepster in 2005, then restored a Cj3a which we did all the work on, and recently sold it. The Surrey is the only old vehicle I ever bought that didn’t require work to be able to drive it home.

I understand the NJ tell it like it is way, so we are OK there.

Colin, I’m glad we reached an understanding, I guess we’re not so far apart after all. Thanks for your commentary and insight, an exchange of thoughts and ideas is always appreciated.

Way to work it out guys !!! and Colin , awesome job on the hoped up Surrey !!! Looks great and I love the aluminum head and dual carbs . Hopefully you can get it reworked and put back on just because !!! Guys have been doing this type stuff for as long as these cool parts have been around and will continue to do so as long as we can be lucky enough to keep finding them . Very nice garage also !!!

Glenn, if you send it to me I’ll publish it.

– Dave

Thanks guys for all the comments, which help

Provide the impetus for me to continue working on the challenges this project has presented!

Colin, years ago when I was still riding motorcycles I used a device called Carb Stix (I believe that was the name) which consisted of four rigid clear plastic tubes connected to a reservoir filled with mercury. Four clear flexible tubes were attached to the upper end of these rigid tubes and these flexible tubes would connect to intake ports on the motorcycle carbs. Two tubes were used for two carbs and four were used on four carb models. With the engine at idle it was a simple way to see the intake vacuum by how high the mercury was in each tube. Match the mercury level at idle then increase the rpm while viewing the mercury levels and adjust as necessary to sync the carbs. It was easy, fast and simple but it worked. Possibly something like this would work on your Surrey carbs.

Aluminum is like saying kleenex … there’s many different alloys with different properties concerning corrosion and strength. Two years ago I sold an aluminum aircraft engine manufactured in 1929, the aluminum was in beautiful shape and the engine will be rebuilt. The aluminum alloy used and the environment the part is used in is a major factor in the life of the part.

Thanks for the info Alaska Paul!

There were lots of cool parts for flatheads back in the day. Adrian made overhead valve heads for flathead fords back then…very rare and expensive stuff today.

The ARDUN heads were made by Zora Arkus Duntov and his brother. Duntov later made his mark with the Corvette and high performance parts for Chevy V8s

You may find the Willys World Newsletter that Glenn is speaking about here;

http://jeepwillysworld.com/the-willys-club/

I just don’t know yet which number it is but I’ll let you know when if I find it.

This thing looks awesome!