Paul’s continuing to make progress on his trailer.

I can’t remember if I explained about the lunette thread damage and what it took to get it repaired so here’s the brief story. Before I began disassembly of my M100 trailer I liberally sprayed all the fasteners with penetrating oil numerous times in hopes of easing the removal process. Most of the nuts and bolts unscrewed with normal effort (including the castle nut on the lunette) but I was disappointed to see some of the threads on the lunette were damaged by the nut when things came apart.

Once the lunette was cleaned and bead blasted I took it to a local machine shop to see what could be done to repair or replace the damaged threads. Because I didn’t know if the lunette was cast or forged the machinist said welding was out of the question and suggested I just buy a replacement lunette. I returned home and made numerous phone calls to military parts sellers, Jeep parts sellers and anyone else I thought might possibly have an M100 lunette for sale. Not only did I come up with a big fat nothing for a replacement lunette I also learned these things are harder to find than unicorns. I made a trip back to the machine shop and had another conversation with the talented folks about the lack of replacement lunettes before we brainstormed about the possibility of thread repairs.

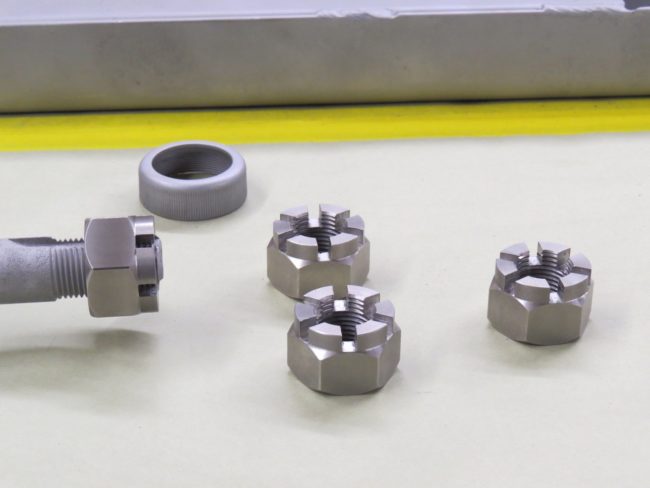

After I answered all their questions about the M100 trailer weight, load capacity and the type of use it will be subjected to a solution was suggested. The plan was to carefully remove the damaged threads and then cut new threads on the slightly smaller diameter of the lunette. The thread pitch would be an uncommon type so they would have to make a castle nut of the correct diameter with matching threads but very little strength would be lost with this repair. I wanted one change made with their repair plan, instead of making one castle nut I wanted them to make four nuts. That way if I ever lost or damaged a special nut I’d have spare nuts on hand.

The attached photo shows the thread damage on the lunette, the focus is poor but the missing threads are still visible.

Here’s the end result of the lunette thread damage and repair story. Not only did these talented machinists rethread the lunette, and fabricate four new castle nuts that match the lunette they even made the replacement castle nuts in stainless steel. I’m a happy guy.

The lunette has been powder coated satin black (to match the rest of the M100 running gear) and tucked away until it’s needed during the reassembly process sometime in the near future.

I’ve got some stainless steel cotter pins the correct diameter and length (left over from my aircraft days) that will be perfect for this modified M100 trailer.

Very professional job! Made to last too! Good job hammering out a solution Paul and Machinist!!

What are the specs for the nut…I need to buy one and these ap[ear difficult to finThanks,

Jamesd.

Are these interchangable with the M105A2 ?

James, in our previous emails a few weeks ago I explained to you the M100 trailer is a 1/4 ton capacity so it’s very different than an M105A2 trailer. I suggested you contact Boyce Equipment for the correct nut for the lunette on your M105A2 trailer. Nothing I have will fit your trailer. If Boyce Equipment couldn’t supply the parts you need did you check with Surplus City or Midwest Military?