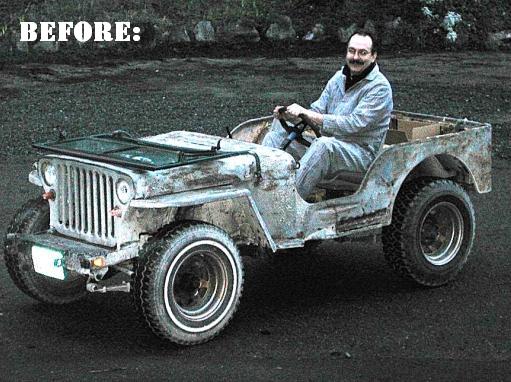

Brian’s been back to work on his CJ-3B. After a bunch of body work and suspension work last fall, he’s got the axle housings where he wants them. So, over the past month he has tackled the creation of some custom driveshafts. Thanks for sharing Brian!

REAR DRIVELINE

Brian writes: “I wanted a CV rear drive shaft so I bought a front drive shaft from a Grand Cherokee for $20.00 off craigslist.

The other pieces shown were removed from stock dive shafts. I thought I would use them for the front. WRONG!

With the help of Mick C. and his lathe we cut the CV shaft down to the size needed. Before installing it I discarded the E-brake assembly and bought a new yoke from Deny’s Drive shaft

http://www.dennysdriveshaft.com/p233_cv_yoke_dana_20_transfer_case_1310_series__10_splines.html

It turns out, the dust shield also needed to be removed when installing it onto the Dana 18.

The result, seen below, is one big beefy rear drive shaft with good travel and articulation.

FOR THE FRONT DRIVELINE:

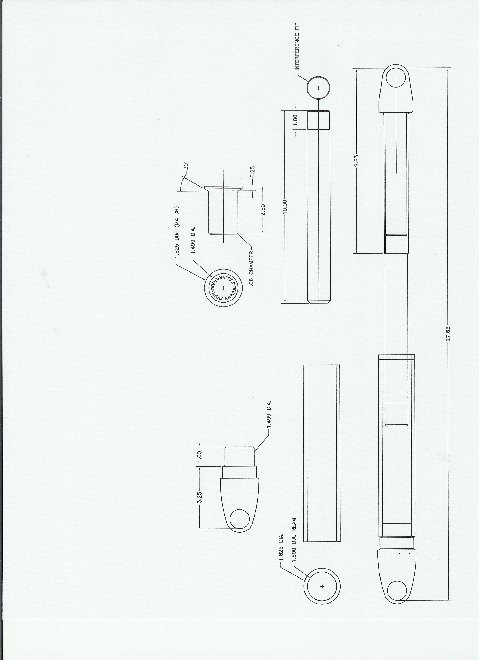

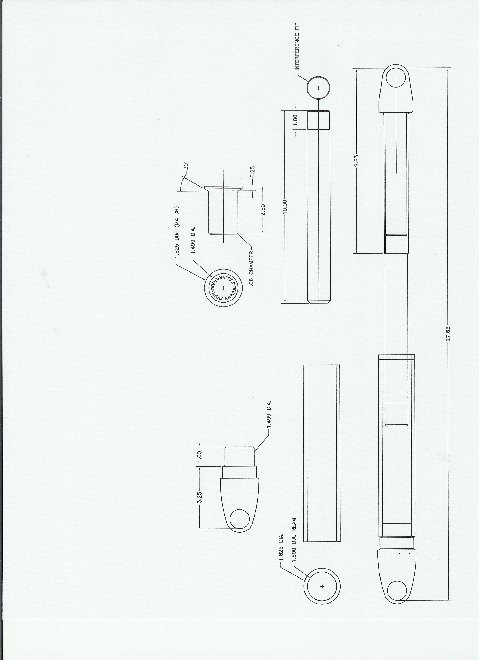

Due to the spring reversal I installed, I decided I needed 4-5 inches of travel, which meant the parts from the stock shafts would not work. I started searching and could not come up with any type of stock shaft I could modify for the travel.

So, I Googled ‘Spline Shafting’ and came up with Grob Inc.

http://www.grobinc.com/coldrolled/std_spline_shafts.htm I selected the 1.185 Dia. 20 spline shafting to build my shaft. The diameters were close to stock but the spine depth is less on the Grob spine.

The rear yoke and tube of the shaft is part of the stock shaft that came with the jeep. Some where in my dealings I already had procured a CJ7 front shaft. So, I took the front 1310 yoke off it to mate it with the Dana 30. Mike and I turned it down and shortened it.

The main body was supplied Mr. Smith, who did it at Chrysler before the shut down. The tube was dressed them reamed at 1.500 ID. Mick C. did the precision turning’s and the fits were a slight interference fit. The spline shafting is made of 1117. I wanted this heat treated so I took it over to: Westside Flame Hardening Inc. http://www.westsideflame.com/cgi-bin/index.pl?init=1

(A Mom and Pop shop just out side of Detroit trying to survive. They only had three pieces in the shop to work on. A lot of people think of the Big Three in the bailout, but there is far more people’s livelihoods disappearing as well.)

Because of the Sm420 I have installed, I had to replace the front yoke and run the small u-joint. I bought my transmission off Dave [ed note .. that would be me] with the adapter from Advanced Adapters. When the big 1310 u-joint did not fit I called AA and they told me I needed to run the small one.

Another problem I had was that the spines were exposed. So, I found a Rancho shock boot and it turned out to fit just right.

For both shafts I spent:

$20.00 for the Grand Cherokee stock shaft

$45.00 for the spine shafting.

$60.00 for having them welded.

$25.00 for Heat treating of the front spines.

The out standing machining on the shaft was done by “Mick” & Mr Smith” and was free. Two custom Shafts for $150.00 Not bad.

I have been working on brakes and the radiator and other small things time permitting I think I can run it down the driveway by late June.

– Brian

[fb_button]

You’ll remember we first met Dan and his CJ-5 from his discussion of his Hudson Steering to Saginaw Swap.

You’ll remember we first met Dan and his CJ-5 from his discussion of his Hudson Steering to Saginaw Swap.