I spent the last couple of days working on the firewall. This is obviously a key element for assembling other items, such as the steering, brake/clutch pedals, gas pedal, etc.

I should begin by noting that we have a new name and theme for the jeep: LEFTOVERS. It’s a food-ish theme that kind of goes with Lost Biscuit. I like that it isn’t a particularly serious name. And, it seems appropriate given I am scavenging two former racing jeeps, but a few parts off of Biscuit, as well as some other random parts.

I saved the original firewall from the yellow-bodied jeep, but it wasn’t in the best shape. I also wasn’t sure if I wanted to use it anyone, because my firewall area includes several rollbar tubes that aren’t present in the yellow-bodied build. Here are some pics of it on the old jeep (btw, I’ve been terrible at taking pics during this build):

I felt the deciding factor would be how well a template I planned to create for the firewall would overlay the old firewall. If close enough, I’d make the old firewall work (again, leftover theme).

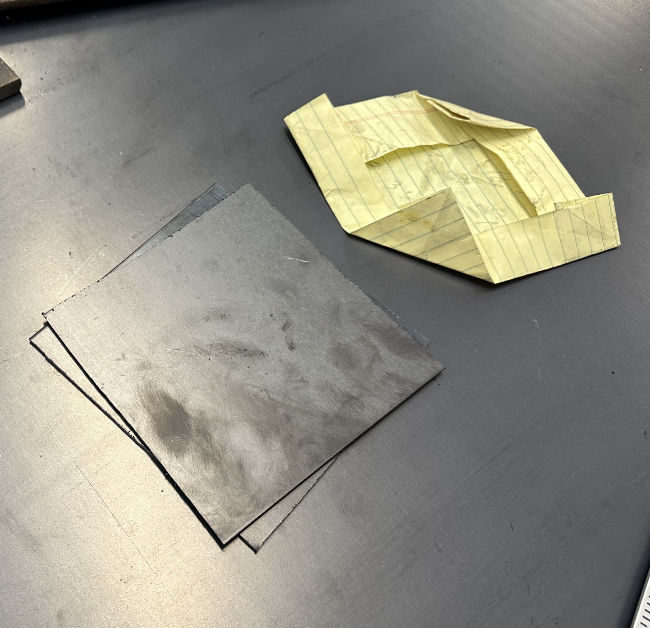

Below is my really fancy paper template (I won’t be using the aluminum cover over the gear box .. I was just experimenting with that).

The first thing I realized was that I would need to split the old firewall in two halves in order to install it and have it fit over the roll bars. Once I was reasonably happy with the template, I laid if over the firewall (no pics of that), only to learn that I would need to flatten most of the existing firewall and rebend it; not an easy task!

Fortunately, the other day I bought a 20-ton press from Harbor Freight (I needed it to fix a neighbor’s plow). I used the press to press the bends relatively flat. Then, I cut the firewall in half and began the process of re-bending the firewall to the specs I needed, then cutting out areas to fit one over the roll bars.

Here’s an example of the passenger side after the top part was was bent flat:

Another obstacle I had to consider was the distributor at the rear of the engine. I needed room to be able to remove that if necessary. Here’s a pic of the two haves bolted to the crossmember I made from spare square tubing. It’s not perfect, but it will look alright once I get the paint off of it and clean up everything else. Besides, it will be hidden under the cowl.

With the cowl in place, I began playing with the steering column. I never liked the way the steering column in the original green-black jeep wiggled. The yellow jeep had a much more solid setup, so I will try to use it. It will need a new steering wheel, as that was damaged when the yellow jeep was wrecked.

Next up will be getting the clutch/brake assembly attached, build the bracket for the clutch slave cylinder, build the covers that go over the center portion of the firewall, and add a few attach points along the side for the firewall. Still plenty to do!

[fb_button]