Colin bought a Hickey aluminum cylinder head to modify his 1960 Surrey, but ran into some problems with it. Below he describes the changes he made, the problems he encountered, and his current solution. Thanks for sharing Colin!

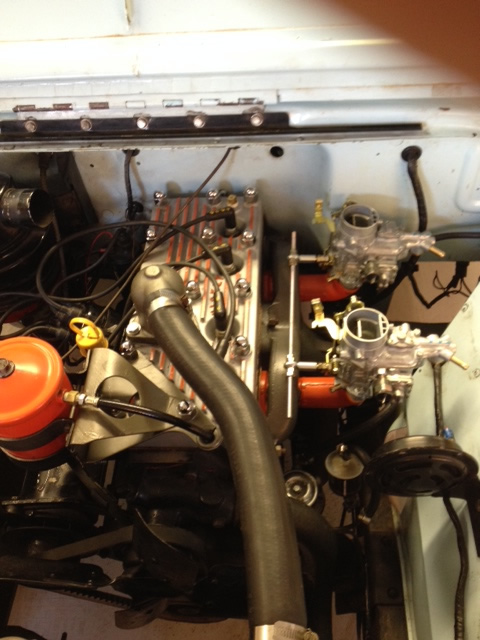

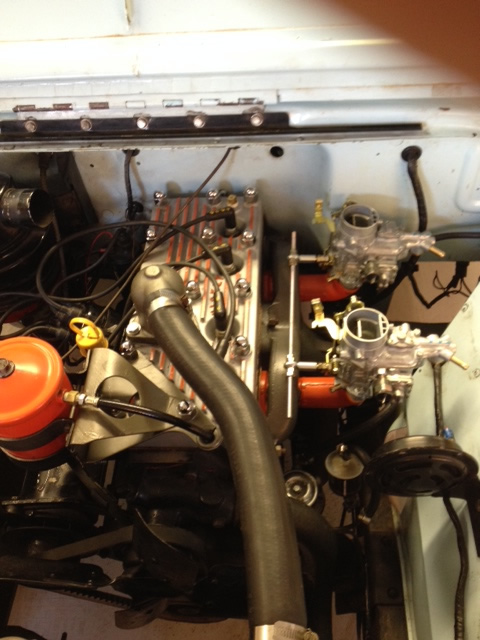

I started a hop-up project on our Surrey that involved the installation of a 1950s Nick Hickey aluminum cylinder head for the L-134. That morphed into the fabrication of a dual carb setup using two intake manifolds with a balance tube an F Head exhaust manifold that a very good friend, Steve Mason, and I fabricated out of an old manifold supplied by Jim Sullivan.

The first issue was the two new Weber carbs. They were supposed to be synchronized and jetted the sam, but weren’t. That led to the rear carb dumping extra fuel into #s 3&4, resulting in a blown head gasket which dumped coolant into those cylinders.

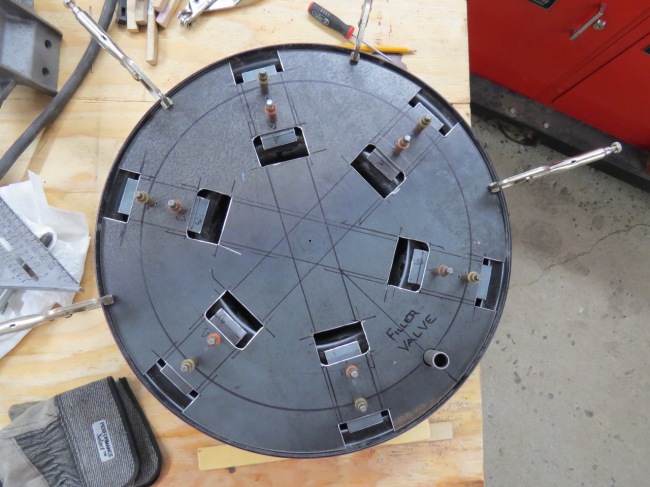

Hickey head top and bottom.

Took it all apart, rejetted the carbs and had the head resurfaced. I finished buttoning everything up and fired it up. adjusted the carbs slightly, running smooth, then noticed coolant in the #2 spark plug recess. Shut it off, pulled all plugs, could see coolant in #2, and steam coming from what must be a crack in the threads.

When I had the engine running previously I did not have water pooling in the plug basins. Upon looking at the plugs, the electrodes indicated the possibility of them coming in contact with the valves. Took a very hi intensity flashlight and looked into the cylinders and at least two of the valves I saw the imprint of the electrode on the valves.

So my theory is this:

I had the head resurfaced and in that process, the machine shop used an epoxy to smooth the surface indentations( corrosion?), and then did the resurface. The plugs I had used were nearly new from the original head. Those electrodes did not extend into the combustion chamber. The machine shop( guys who do a lot of work on Ford V8s with aluminum heads told me to get plugs with a slightly longer shank for better combustion. So I did. Only a small imperceptible difference in length.

Continue reading →

Continue reading →

[fb_button]