Titled, the “CJ-2A 1948 Willys Overland Jeep Restoration Project“, this blog follows the rebuilding of a 1948 Willys by Mac and Jason in Houston, Tx. It’s clear they don’t know a great deal about jeeps (neither did I when I started on my jeep many years ago), but are jumping in with both feet none-the-less. Kudos to them; it looks like they are learning already.

Features Research Archives

Photos – From “03Jeepgirl”

I was doing some research and found some pics from a female photographer on flickr who calls herself 03Jeepgirl. She owns two jeeps, though she didn’t get specific about what she owns. She’s posted a large number of old vehicle pics, including these flattie shots.

Builds: Josh’s WW2 US Navy Converto T6 Trailer

Josh sent over some pics of a very rare WW2 US Navy Converto T6 Trailer. Josh is curious to know if any other readers have or know of these trailers. I’ll be happy to set aside some space for Converto trailer owners to gather and share information.

Also, he’s got another trailer for sale on eBay (Converto Airborne Dump Trailer — see post below this one).

Josh writes, “Here are some pictures of my WW2 US Navy Converto T6 trailer I mentioned to you a while back. I found it here in Boise, though it was never advertised for sale. It is almost identical to a more well known Bantam t3 or a Willys MBT. During the war there were a number of companies producing nearly identical trailers for the military. The only notable difference between my MBT or T3 and the Converto T6 are a different brake hand set up, dataplate, and, in the case of my trailer, a ball hitch that is stamped USN 1944. (My hitch is different from the two other Converto T6s I’ve heard about — They both have the standard military lunettes) The data plate was originally riveted to my trailer but the past owner removed it to paint it grey again with spray paint. The under side of my trailer has what I believe to be the original paint and some yellow stenciling that has shipping info/load info. I plan to fully restore and hold onto this T6.

Converto also produced a T7 (same 1/4 ton trailer as the MBT/T3/T6 but with a tailgate) and a Converto Airborne Dump Trailer which is a 1/2 ton but used with the jeep. There is really little info I can find out on either the T6 orT7, but the Dump trailers do have a lot of info available including a military TM. I have had a few Converto Airborne Dump Trailers. They are very hard to find as it is estimated only about 6500 where produced. I’m unsure how many T6/T7 were produced. Not very many based on how few are still around. Maybe we can find a few more with your readers??”

Club Run: Flatties on the Slick Rock in Utah

I’ve seen lots of pics of modified vehicles that crawl the slickrock of Southern Utah; so. it’s a nice change to see these two classic jeeps cover the trails without issue.

Randall writes, I thought maybe some other old school jeepers might like to see a few photos of a recent club outing to Moab. The jeeps did great and the scenery was absolutely awesome. The “slickrock” on “Fins&Things” and “Hell’s Revenge” trails was amazing.

The M38 is a 1952, all stock with four banger, T-90, and Dana 44 with 5:38’s. The other is a ’52 3A. Also bone stock with Dana 41. The only upgrade on it is 11″ brakes and 12v. This was our first trip, but probably won’t be our last. We went the first week of Nov. and hit great weather by luck. We’d hoped to have more jeeps make it but too many conflicts for everyone. Had a blast with just four of us in the two jeeps. They climbed just about anything a sane, middle aged man would need to climb and the gears made descents very doable with little need for much braking. HOWEVER, I was glad the brakes were in very good condition when we first went down some of the trails.

Duke Edwards == Hot Rod Artist

I found the image below on eBay. The bidding has ended, but I”m sure it will return. I thought it looked very similar to Brian’s CJ-3B (or former CJ-3B — did you ever sell it?). After located a pic of the CJ-3B, I concluded it must have been used as the model of the drawing.

One image below is the drawing and one is a shot of the CJ-3B from the CJ-3B page (See more pics of it there — It’s a beauty!).

According to an old ebay listing, this particularly drawing is a run of 250 prints of a drawing by artist Duke Edwards. I didn’t know who Duke Edwards was, so I did a google search and found the information below from the ‘Automotive Art Gallery‘.

“Duke has been “doodling” for almost 40 years but had limited his clientele to friends and local car clubs. Since making his work available to the public, he has received international recognition and has pieces on museum display as well as in private collections. For just “doodling” Duke is amazingly talented.”

Old Pics: Phil Nelson’s Place

UPDATE: Bob also snapped a picture at Phil Nelson’s Place in Columbiana. You can see it below.

I’ve never been there, but these are some great pics of the place from Gerald.

“A small display outside of Phil Nelson’s place in Columbiana Ohio. It is truely a treasure.”

L-head and F-head performance

I found this article on Automotive.com, though it’s really an article from JP Magazine. The article highlights improving performance on a variety of Jeep engines. Here’s two excerpts and a great pic.

“Dual carburetor manifolds in the ’50s were available for just about any engine you could imagine and an old-time company, Burns, made a log-type manifold that utilized two Stromberg Ford V-8 carburetors for the Jeep four-cylinder. I’m sure these helped the four-cylinder flathead’s performance, but, still, the long-stroke 134.2ci engine needed a lot more than this…”

And a little on the F-head

“The next step was to swap in a later model F-head engine. It wasn’t technically an engine swap because it was a direct bolt in. Still the same basic engine, but a new cylinder head design with the intake valves upstairs in the head instead of the block. Depending on the compression ratio, which ranged from 6.9 to 7.8 (depending on year and usage), it was rated at 72 to 75 horsepower at around 4,000 rpm and torque was up to 114lb-ft. This one got a balance job, some performance pistons from Speed-O-Motive, and a Holley carb from a Falcon six. My new performance motor maybe made 100 horsepower on a good, damp day.

Harry Buschert, who owned a farm implement repair shop in Hemet, California, was a real innovator in design. He built up a very-modified, four-cylinder F-head that even had a Paxton Blower that he had salvaged off a Packard….”

Jim Boswell’s Seat Cushions

UPDATE: Jim used to make these seat cushions, but no longer does. I’ve decided to keep these here just in case someone is looking for ideas for Seat Cushions.

Builds: More on Paul’s Stainless M-38

If you haven’t yet read about Pauls M-38 project, go to installment 1 and installment 2.

Paul, take it away …

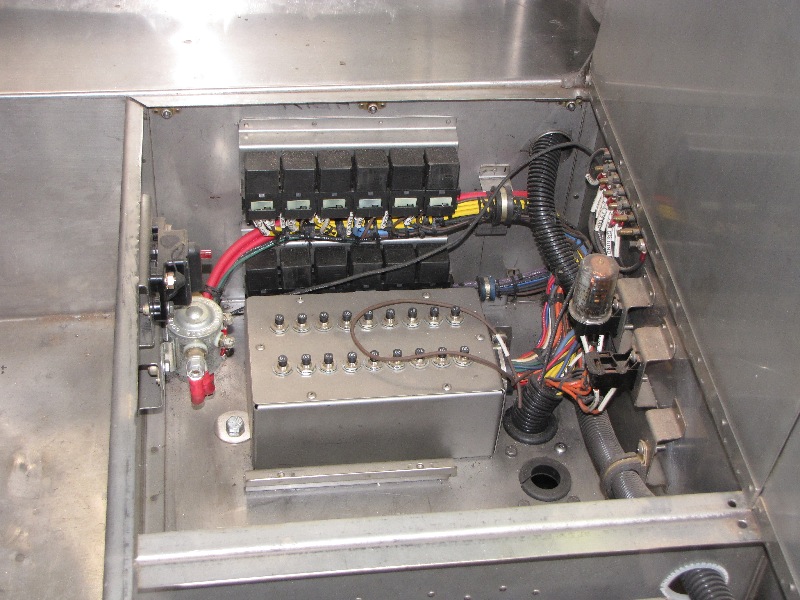

Paul Bierman again with a few more pictures of the never ending Willys project. I didn’t want a rear seat (Who can fit back there anyway?) so I fabricated a storage box which spans between the rear wheel wells and is divided into two sections. The half behind the passengers seat is the new battery location along with the circuit breaker panel, the master relay and circuit breaker and most of the switch relays. The half behind the driver’s side is the home of a now vintage (but it’s still brand new, I bought it quite a while ago) ten disc cd changer with some room left over for an out of view storage compartment. I’ve replaced just about all of the wiring with new (there’s some original wiring on the gas heater still but I’ll get to that sometime) with some fancy pants, super flexible cold weather wiring which stays flexible down to 55 below zero F. Boy, doesn’t that just make you feel dandy. If it’s that cold I’ll wait till spring, besides I try to draw the line on outside work when the temperature drops past 40 below zero F, nothing’s worse than having to take a leak when you’re wearing multiple layers of clothing eight inches thick and Little Mr. Wizzard shrunk up to an inch and a half. No matter what you do you know at least one of your boots is going to get wet.

Moving the instrument panel above the windshield caused still more problems but the most annoying one was how I could get all the wires from the gauges down to the main body without my work looking like crap. I was at work thinking this over (Ok, I was in the bathroom but I do my deepest thinking sitting down) when I happened to glance over at the wall and saw a beautiful stainless steel handle just the right size with curved ends, satin finished and everything! Problem solved, until I mentioned this great solution to my boss and his exact response was, “Touch it and die.” Geeze, guess I’ll have to spend my own money and purchase some handicap grab handles. The local home supply store had quite a selection of stainless handles but I ran into a problem with an over enthusiastic clerk wanting to help me with my bathroom remodel. He’d never heard of a 52 Willys bathroom renovation. The handles worked out great, you can see them on the pictures of the windshield/instrument panel photos by the door posts.

Winter was late getting here (I love global warming!) but I have lots of cold dark days ahead of me so the Willys will get a great deal of attention before this latest batch of snow melts. Next week I’ll have the side and rear window glass cut and then I’ll have to make patterns for the door window glass and they’ll be ordered when my wallet says it’s ok.

PS … I’ve really enjoyed the comments left by fellow Willys wackos, the concern about welding above the jerry can was nice but the can had never been used and I threw it out after I’d made the gas can mount. If I was to worry about welding safety I should have thought about the beef and bean burrito (with cheese and onions on top) I’d eaten for lunch, not so much for the flamability aspect (the poor garage just isn’t that tightly sealed) but the thrust developed after lunch could have blown me off those fancy bucket workstands!

Some Registered Trademarks of Daimler Chrysler

I was doing some research on which Registered Trademarks relating to Willys or Jeep were related to Daimler, Chrysler (D/C) or their subsidiaries (and I was surprised at how many of these are owned by different subsidiaries within the D/C organizations).

A short primer on Trademarks. Registered Trademarks are applied for with the United States Patent and Trademark Office. If the Office thinks you have a good case, they’ll grant you a trademark. Sometimes you apply for a trademark with just words OR sometimes you apply with the words in a particular design.

When you apply for a Trademark, you apply for 1 or more different classes, with each class costing currently between $275 – $325. As you see below, over the years, D/C has applied for additional Trademarks over additional types of goods and services (and in fact has applied for and then abandon some other categories also which I don’t list).

So, if you aren’t bored yet, keep on reading. Below, I’ve listed all the valid Willys, Jeep and some other interesting Trademarks. First, you’ll see the Trademarked Name, followed by the Registration number of the Trademark, and finally, notes about the particular Class for which the Trademark was granted. In most cases, you’ll also see the year when it was first used in commerce, which is important for protecting your rights of ownership.

1) I was surprised to see that D/C only has registered trademarks for WILLYS in two classes, which is good for me because it leaves a large number of Willys names open should I want to Trademark some additional names.

A) Willys 2722568 IC 028 TOYS, NAMELY, MODEL REPLICAS OF LAND VEHICLES.

B) Willys 3387789 IC 012 G & S: Automobiles.

MUCH MUCH MORE ON THE NEXT PAGE