Winter has a funny way of blowing all kind of things into and around the garage. Last November I took a break from projects in the garage, but when I went out there a couple of weeks ago, it was a bigger mess than I remembered it. So, I spent last weekend cleaning (including cleaning out the parts washer — uggh), organizing and getting ready to attack my first project of the year, getting the disc brake parts cleaned up and painted.

Winter has a funny way of blowing all kind of things into and around the garage. Last November I took a break from projects in the garage, but when I went out there a couple of weeks ago, it was a bigger mess than I remembered it. So, I spent last weekend cleaning (including cleaning out the parts washer — uggh), organizing and getting ready to attack my first project of the year, getting the disc brake parts cleaned up and painted.

So, when I went out today to start with the brake parts, naturally I ran into problems.

So, when I went out today to start with the brake parts, naturally I ran into problems.

PROBLEM 1: My parts washer repaid my efforts at cleaning by developing a leak at the base of the pump. Not cool. Since this parts washer is older than some of the wagon wheel trails around here, I’m not entirely sure if I can find parts for it. It’s entirely possible it’s a custom tank. So, I get to spend this upcoming weekend removing the washing liquid and attempting to patch the leak.

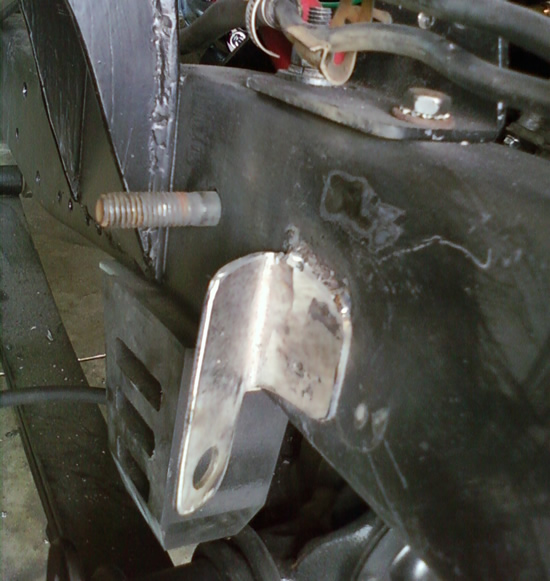

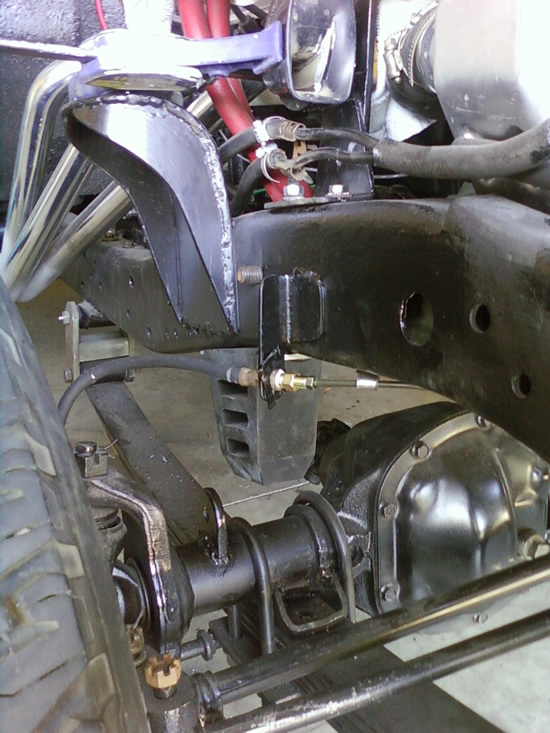

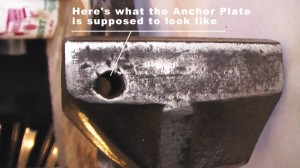

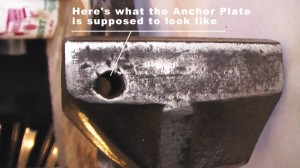

PROBLEM 2: Since the parts washer wasn’t going to work, I decided to use a wire brush and a sander to clean up the parts. So, I cleaned up one of the anchor plates, no problem. I got to the second anchor plate and noticed that what’s supposed to look like a hole with threads had chunks missing and the threads are gone. Having not worked with these brakes before, I decided it was time to close up the garage for the day and hop on the internet to see if I could learn more about the problem. Unfortunately, I couldn’t find anything about the problem.

PROBLEM 2: Since the parts washer wasn’t going to work, I decided to use a wire brush and a sander to clean up the parts. So, I cleaned up one of the anchor plates, no problem. I got to the second anchor plate and noticed that what’s supposed to look like a hole with threads had chunks missing and the threads are gone. Having not worked with these brakes before, I decided it was time to close up the garage for the day and hop on the internet to see if I could learn more about the problem. Unfortunately, I couldn’t find anything about the problem.

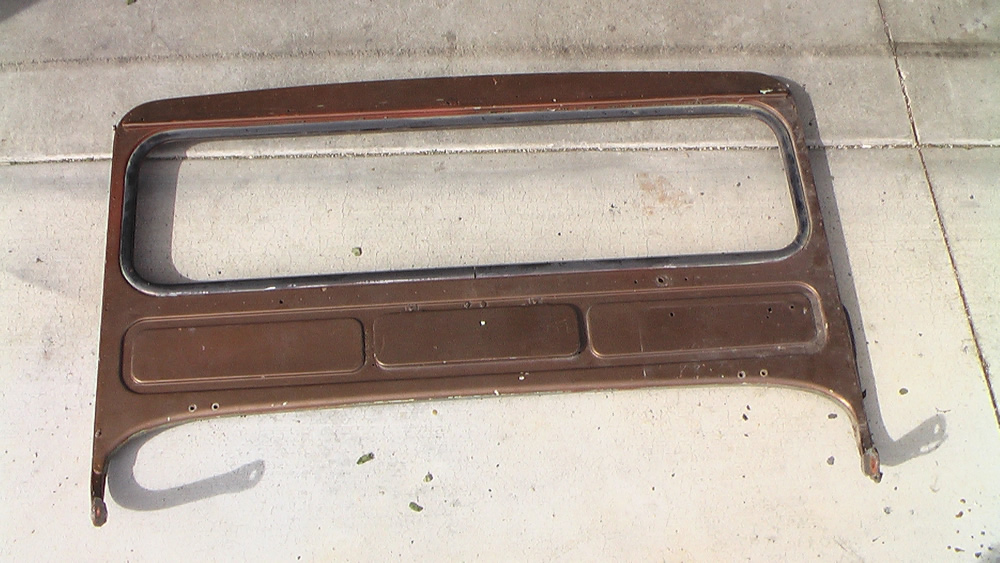

So dear readers, what’s the bolt for? Is it important? I’ve got two images to the right. The image at the top shows the entire anchor plate. The second pic highlights a correct hole and the bottom image highlights the problem and shows the bolt that should go there? Do I need the bolt (of course, I’m sure I do)?

[fb_button]