Paul continues to make progress on his build, though he does have a habit of becoming side-tracked with wood projects (if I am a Foodie, he is a Woodie).

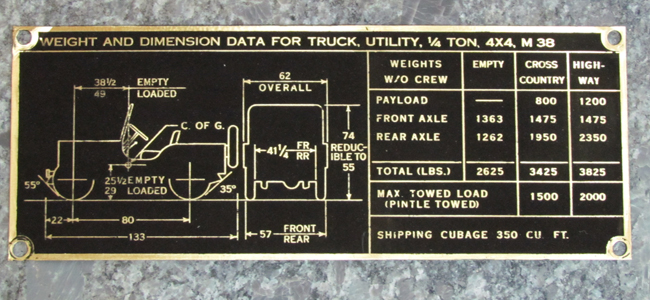

Paul writes, “The local exotic wood store has been letting me pick over the wood shipments right after they’re unloaded and this has caused some trouble with overheating my credit card. While I’m still making progress on the never ending Willys project, money has been in short supply so many of these projects have to be low buck items. One of the cheaper but necessary jobs was to repaint the brass data plates (a total of six plates) originally installed on the M 38. While I really wasn’t looking forward to working on these plates ( lots of trouble for very little progress) I felt the appearance of the Willys would be improved by having bright and shiny data plates installed on the heater duct below the base of the windshield.

I use a really strong liquid paint stripper to remove the original black paint from the data plates. After the paint is gone I do a chemical wipe with lacquer thinner then gently rub the bare brass with a fine grade scotch pad before doing another chemical wipe followed by the spray can black. Cheap, easy, and quite time consuming but the finished plate looks pretty good.

While it isn’t difficult to redo these data plates it is real easy to screw up the paint (once the new paint is applied) while cleaning off the lettering and then have to start all over again. I’m using rattle can glossy black spray paint to apply two light coats on each plate and I let them dry for one day after the second coat. After the paint is dry I very carefully block sand the plate with 400 grit sandpaper with the plate supported on a thick, flat surface. I’m using a 3/4 inch thick slab of granite (it’s flat and cheap) so if I didn’t damage the paint during the sanding process I spray a very light coat of clear over the data plate and let it dry for another day. Don’t spray a heavy coat of clear, it lifts the black paint which results in more clean up time and then you have to start all over. I figured this out the hard way so you wouldn’t have too. Geeze, what a guy!

Anyway, if things went well you should have a new appearing data plate to attach to your Willys. I’m still working on the remaining four plates because I got a little careless while sanding but the first two plates look pretty good. I’ve attached three pictures showing the stages of data plate repainting.

1. Cleaned Plates with paint removed.

2. After paint is applied.

3. After paint is lightly sanded off.