If you haven’t yet read about Pauls M-38 project, go to installment 1 and installment 2.

Paul, take it away …

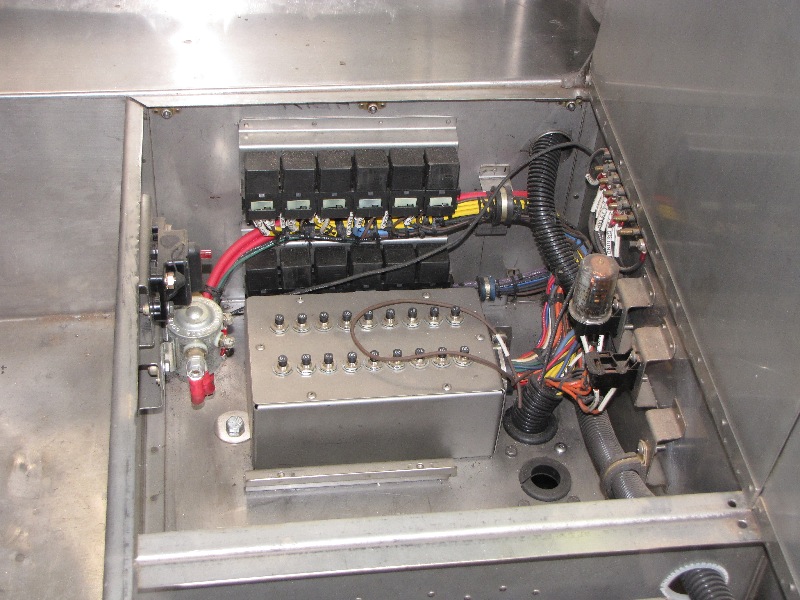

Paul Bierman again with a few more pictures of the never ending Willys project. I didn’t want a rear seat (Who can fit back there anyway?) so I fabricated a storage box which spans between the rear wheel wells and is divided into two sections. The half behind the passengers seat is the new battery location along with the circuit breaker panel, the master relay and circuit breaker and most of the switch relays. The half behind the driver’s side is the home of a now vintage (but it’s still brand new, I bought it quite a while ago) ten disc cd changer with some room left over for an out of view storage compartment. I’ve replaced just about all of the wiring with new (there’s some original wiring on the gas heater still but I’ll get to that sometime) with some fancy pants, super flexible cold weather wiring which stays flexible down to 55 below zero F. Boy, doesn’t that just make you feel dandy. If it’s that cold I’ll wait till spring, besides I try to draw the line on outside work when the temperature drops past 40 below zero F, nothing’s worse than having to take a leak when you’re wearing multiple layers of clothing eight inches thick and Little Mr. Wizzard shrunk up to an inch and a half. No matter what you do you know at least one of your boots is going to get wet.

Moving the instrument panel above the windshield caused still more problems but the most annoying one was how I could get all the wires from the gauges down to the main body without my work looking like crap. I was at work thinking this over (Ok, I was in the bathroom but I do my deepest thinking sitting down) when I happened to glance over at the wall and saw a beautiful stainless steel handle just the right size with curved ends, satin finished and everything! Problem solved, until I mentioned this great solution to my boss and his exact response was, “Touch it and die.” Geeze, guess I’ll have to spend my own money and purchase some handicap grab handles. The local home supply store had quite a selection of stainless handles but I ran into a problem with an over enthusiastic clerk wanting to help me with my bathroom remodel. He’d never heard of a 52 Willys bathroom renovation. The handles worked out great, you can see them on the pictures of the windshield/instrument panel photos by the door posts.

Winter was late getting here (I love global warming!) but I have lots of cold dark days ahead of me so the Willys will get a great deal of attention before this latest batch of snow melts. Next week I’ll have the side and rear window glass cut and then I’ll have to make patterns for the door window glass and they’ll be ordered when my wallet says it’s ok.

PS … I’ve really enjoyed the comments left by fellow Willys wackos, the concern about welding above the jerry can was nice but the can had never been used and I threw it out after I’d made the gas can mount. If I was to worry about welding safety I should have thought about the beef and bean burrito (with cheese and onions on top) I’d eaten for lunch, not so much for the flamability aspect (the poor garage just isn’t that tightly sealed) but the thrust developed after lunch could have blown me off those fancy bucket workstands!

“Touch it and Die” ……..

You may have willys addiction combined with other ailments.

Your rig is a work of art.

Very nice work….could you move closer to me?

to-shay on the jerry-can…and I spotted another project….’30 Roadster? Need to warm up, head my way – Atlanta, Georgia, extra bedroom plus a ’62 Wagon to play with.

Pingback: Remember to Play with your Willys … | eWillys

With the views Paul has to look at, when does he have time for his beautiful project….heaven is his zip code….

Hello Paul, Did you cut your rear wheel wells, and move the seat back a bit? I have a ’68 CJ-5, and am 6’2″, 240 lbs, and find it hard to fit under the steering wheel. How much can I cut out of the wheel well? Do you have anything in your posts on how you did this? Thanks much, Bob Coombes. Longmont, CO

Bob, I also needed to move the front seats aft due to clearance issues and this required cutting the front skins of the rear wheel wells and making replacement panels to fit the modified area. If you look at the new upholstery pictures in Paul’s Getting Serious you’ll see how much I cut from the right rear wheel well. A flat fender Jeep will never be called roomy but it is possible to stuff a bigger person in the front seats. When I’m sitting in the driver’s seat I can still see out the windshield but the side windows are too low to do me much good. If I removed the left rear side window my left arm would rest comfortably on the side skin as my elbow hung out in the breeze. I’m 6’5″ but I don’t know how much I weigh since I haven’t stood on a scale for 30 years. I figure if I have to get a running start to squeeze thru the doorway it might be time for me to eat a bit less.