When I built my first jeep, I used the gas pedal from a CJ-5. It was fine for driving around on flat smooth roads, but when I hit a bump, my foot tended to flop against it, which meant I would accelerate unintentionally. It was just too sensitive an arrangement (dad used a CJ-5 pedal in his CJ too and had the same problem).

Eventually, I found a solution to the pedal problem. However, it took a bad day of racing to get there ….

Early in the Spring of 1985 I was at a PNW race competing in a team relay event somewhere north of Everett, Wa. I remember the conditions clearly: It was cold, it was damp, and it was rainy.

Jim, Tim, and Steve Carter and I teamed up for the relay event. Between us we had three jeeps (my jeep, Otis and Priority I — or maybe II or III — I can’t keep track of all the Priority versions …).

It seems to me we advanced to the first round with no issues. However, during the second round, things went awry. Frankly, the precise details of how the rest of the race played out have faded with time. What I do remember is this; First, my front driveline broke as I made my way around the course. Then, when driving Priority, I broke its front drive line. Finally, when driving Otis, I was trying to drive carefully as I REALLY, REALLY didn’t want to break another driveline. At one point I got a little stuck (it was really muddy) and thought I had broke it (ugh!). Fortunately I didn’t … I was perfectly happy to stop racing that day (we got eliminated in the 3rd round I think).

I tell this story, because while racing Otis, I noticed that my foot didn’t bounce and nor did the pedal no matter what bumps I encountered. It was solid, yet the pedal depressed when necessary.

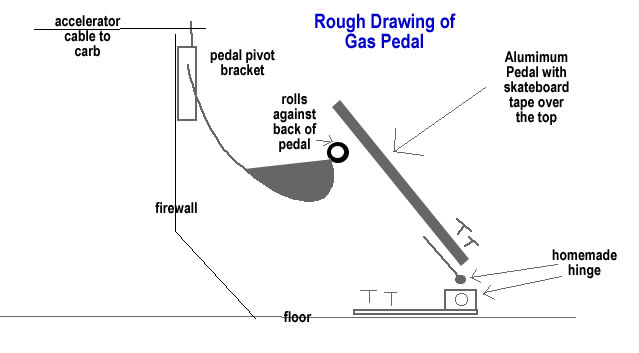

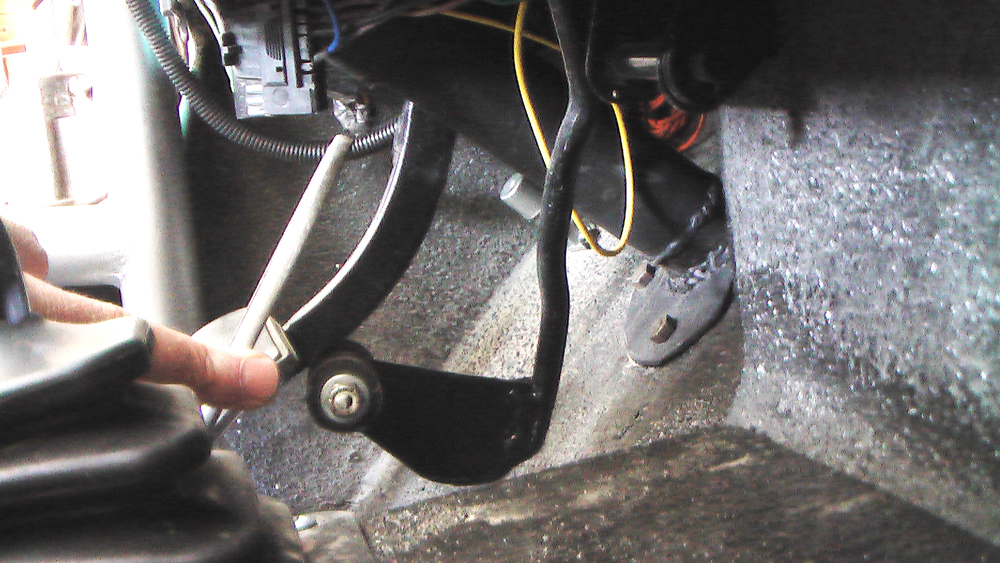

Later in the day, after racing, I looked at Otis’ pedal and discovered Jim had set it up so that the there was a roller behind the pedal. While more complicated than the normal pedal, it really improved the ability to keep driving and accelerating smoothly over bumps.

So, I implemented that in my first build and loved the results. I had hoped to implement the same thing in Biscuit using a classic foot shaped pedal like the Moon Aluminum Pedal. However, I couldn’t justify the cost (read here that my budget was getting tight), so I implemented what I call Version 1.0 of the pedal.

Using some aluminum plate I already had, I drew the shape of my foot onto the plate, cut it out, and then shaped it with my grinder. Then, I went down to a locate skateboard shop and purchased some skateboard covering (sandpaper-like on the front and sticky on the back). I cut the covering into the shape of the foot and stuck it onto the plate. It isn’t beautiful, but it works well.

I’d like to clean up some of the rough edges in Version 2.0. Below are some pics and a highly(?) technical schematic.

BTW, that race was the last day I broke a driveline. I’ve never had a problem since.