Maury spotted this jeep-family ad from Kaiser-Willys of Canada.

View all the information on eBay

“1956 Canadian Kaiser Willys print ad Jeep Universal, Wagon, & Pickup. Original magazine advertisement measures 7 X 9.5 inches (approx.).”

Maury spotted this jeep-family ad from Kaiser-Willys of Canada.

View all the information on eBay

“1956 Canadian Kaiser Willys print ad Jeep Universal, Wagon, & Pickup. Original magazine advertisement measures 7 X 9.5 inches (approx.).”

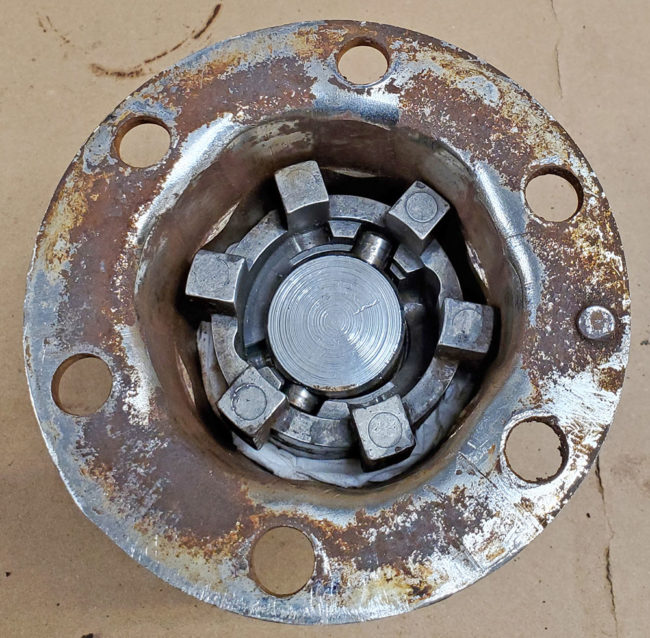

John recently rebuilt a set of Cutlas Selective Hubs, the type with the knob that rotates to engage and disengage the hub. There appear to be at least two styles of these hubs, one with a flat top and one with a groove, so that a tool (or improvised tool) can be used to help engage, disengage the hub.

This exploded overview from 1961 shows how the parts assemble (see the full brochure below this post):

As you can kind of see from this diagram, there are two sections: 1) is the hub cap that holds the knob and the spring in place (from part 107-2 in the middle and everything to the right of it) and 2) the hub base (part 108-2 and everything to the left of it).

John wrote, “Overall I’d say these are my favorite hubs I’ve worked on so far. I have a pair of Warn hubs (with the tiny needle bearings) and a pair of Selectro hubs (big chrome knob type). The Warns seemed like a real pain to rebuild since the needle bearing were in rough shape. And the Selectro hubs, while very easy to operate, were probably the weakest design I’ve seen.”

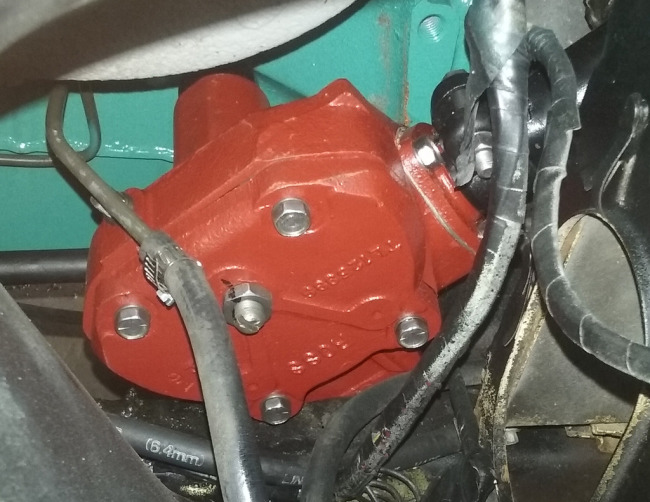

Here’s a look at John’s finished product, as it’s the best example a complete hub next to a hub with the top separated from the base:

I went with a 2 tone paint job just for fun. If it doesn’t last for any reason I’ll end up with the whole thing gloss black and a chrome knob. The body was so badly pitted there was no saving the original finish

HUB CAP:

We’ll start with the hub’s cap first. John provided the following note: “To remove the coupling piece (part 102-2 Coupling) from the chrome cap (with the cutlas knob) you have to line it up right with the correct groove, then push down firmly against the spring inside (part 110-2 coupling spring). While pushing down spin the coupling, and then the coupling spring will pop the coupling right out and its free.”

With the inner portion of the cap apart, you can see the coupling ring, the coupling, the coupling cam spring (part 107-2) and the coupling cam pins (parts 105-2).

Maury published a forum-thread on rebuilding his Ross Steering Box. He (and I) thought you all might find it interesting, too. He also wanted to ackowledge Moses Ludel for all his help (read their exchange here).

Maury published a forum-thread on rebuilding his Ross Steering Box. He (and I) thought you all might find it interesting, too. He also wanted to ackowledge Moses Ludel for all his help (read their exchange here).

This is the link to their subsequent installation & alignment thread: http://forums.4wdmechanix.com/topic/747-ross-tl-steering-gear-installation-and-wheel-alignment/

Here’s a note about Maury’s experience:

I suspect everyone knows who Moses Ludel is, as he has been involved with jeeps at a professional level for several decades. As you may be aware, he has written several excellent books on jeep rebuilding and maintenance, including the Jeep CJ Rebuilders Manuals and the Jeep Owner’s Bible. He is the administrator of the 4WD Mechanix website as well.

The original Ross TL steering gear in my 1967 V6 CJ5 badly needed rebuilding, and I really wanted to accomplish this with NOS parts to the greatest extent possible. Late last year, in researching possibilities for having the rebuild work done professionally, I came across a video on Moses’ website about rebuilding the Ross boxes in which he rebuilt one for a client. I contacted him to ask if he was still doing that kind of work on the side. He responded that he is not, but in short order, he got me interested in doing the rebuild myself. Moses offered to assist me through the process by helping me create a pictorial thread on his website, through which he could advise me as I worked through it one step at a time.

The resulting process of finding the parts and fully rebuilding and installing two Ross TL boxes (mine and my brother in law’s) is thoroughly documented in the two threads linked to above. The first thread is on the rebuilding process itself, and the second covers the installation and alignment of the gear. I found the DIY approach to be very rewarding, including the fact that I “had” to acquire several tools I didn’t own or know how to use before.

Moses’ help and advice were invaluable in successfully completing this project. He is a true guru of all things jeep, and I am grateful that he very generously spent so much time guiding me through this process. I hope these threads will be equally helpful to others who decide to try rebuilding their Ross gearboxes themselves.

UPDATE: Hard to believe it has been almost three years since I published this post!

I discovered these directions for the Muller Custom Top in the August 1965 issue of Four Wheeler Magazine that we’ve seen on nicely modified Fresno area Jeeps. I’m considering building one of these for Biscuit and selling my Kayline.