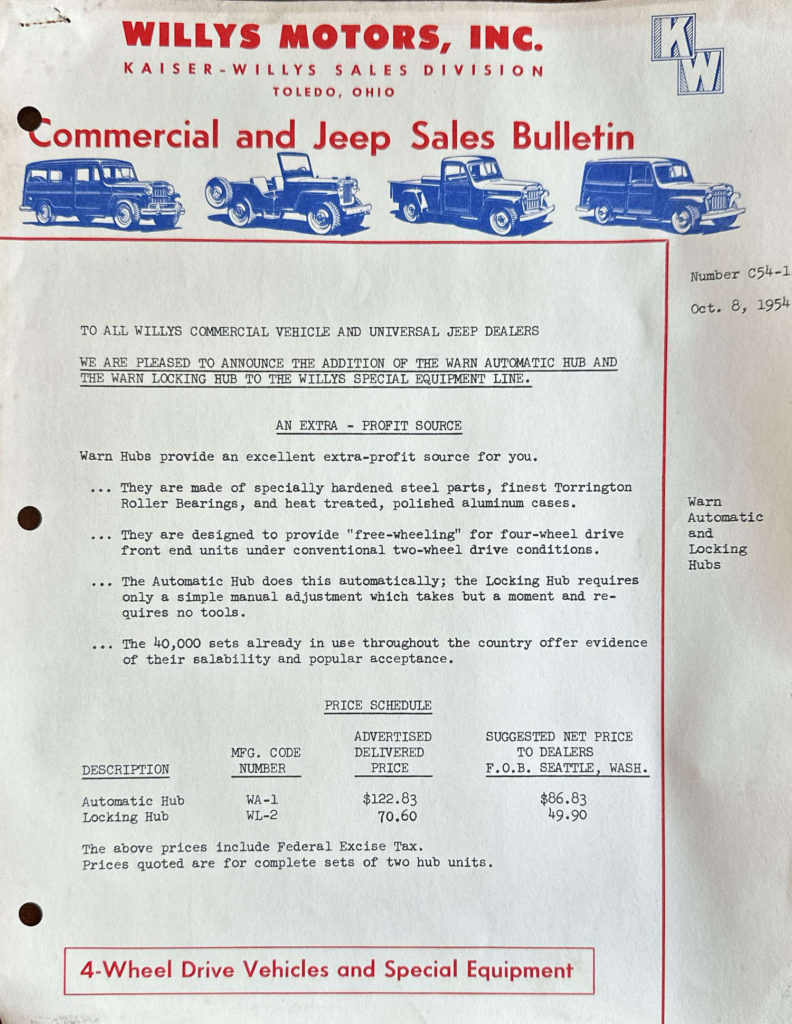

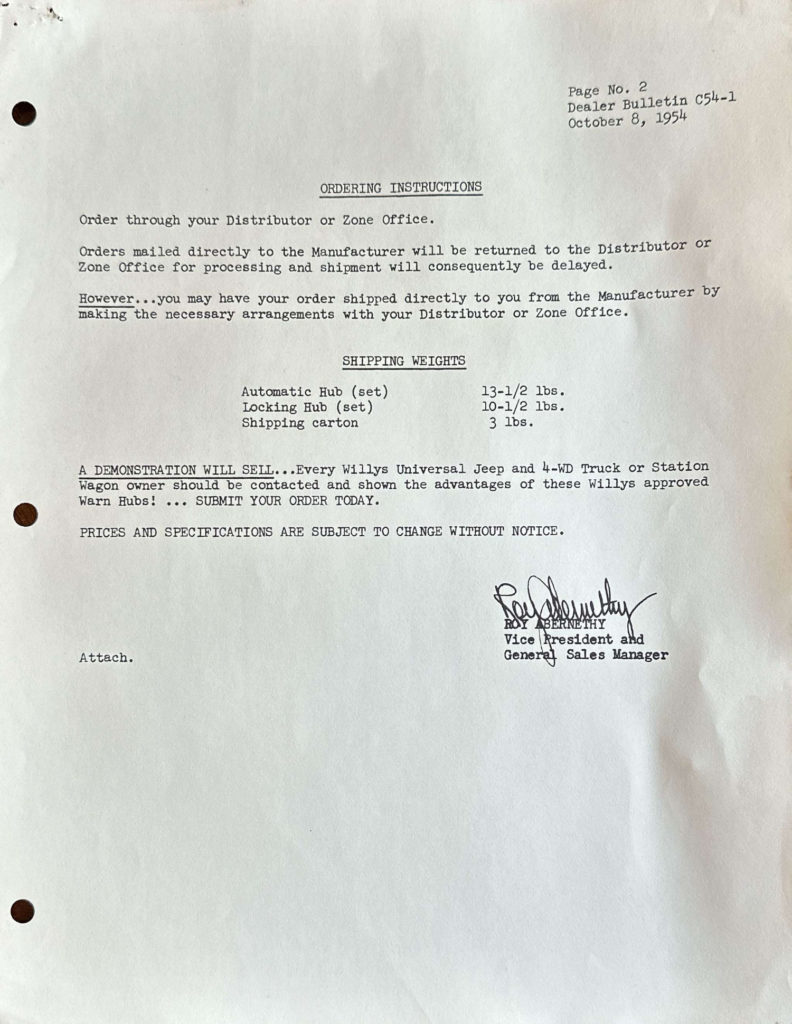

I wasn’t aware that Kaiser Willys put out a series of Commercial and Jeep Sales Bulletins, but I now have examples of at least four of these that I will publish over the next week or so. It’s unclear how many were published or how long this lasted.

This particular example, dated October 08, 1954, welcomed Warn Locking and Automatic hubs to the Willys Special Equipment Line. To the best of my knowledge, it was the first time Willys included hubs in its Special Equipment line. As of 1954, Warn was likely the largest producers of hubs. Free-Lock quickly became the second largest producer of hubs, but that wouldn’t be until 1956 (See Free-Lock Hubs history for more info). To the best of my knowledge, Free-Lock was never added to the Willys Special Equipment Line.