NAME NEWS: The name Gus has been retired in favor of Lost Biscuit.

NAME NEWS: The name Gus has been retired in favor of Lost Biscuit.

For two years I’ve called my project Gus. It all started with a hunk of flattie junk I towed home more than two years ago. As you can see from the pic to the right, the grille is rough and full of personality. It just looked like a Gus.

Over the following months I traded parts and pieces away until I finally gave away the last piece, the grille, to Mitch because I had decided against using the grille. However, the name continued to stick.

During the past month, I was playing some xBox online with my sons, specifically Call of Duty World at War (It’s a kick to play). Karson couldn’t find a username he wanted so he just picked two random words and came up with FoundedBiscuit. His brother, Colter, wanted his own handle and came up with LostBiscuit. During the summer we became Team Biscuit.

The first time I heard it, I told them I thought that Lost Biscuit would be a great Jeep name. After thinking it over and asking them a couple day ago, we agreed that Gus should be renamed Lost Biscuit. Given that I’m a former chef who still loves to cook, having a food as part of the name is entirely appropriate.

PROGRESS

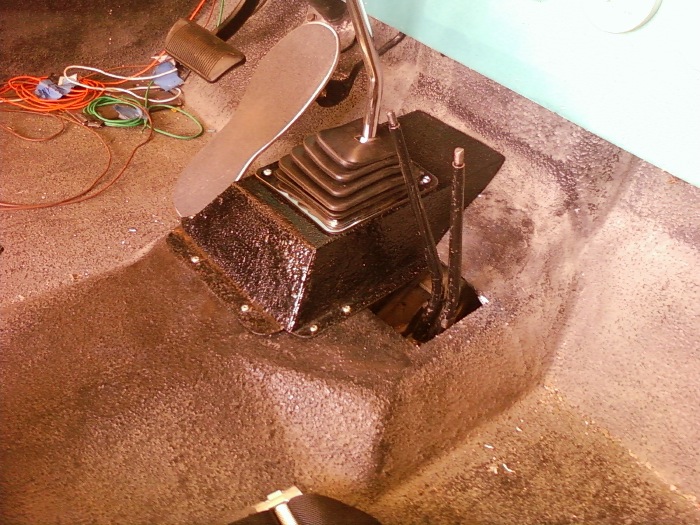

Drove Down the Street: Today marks the first day I drove Biscuit out of the garage and down the street, very slowly. The first thing I discovered is that power brakes work really well. I’m thrilled with them so far. The th350 also feels great — I thought there’d be a little lag in drive like I feel in some vehicles with an automatic, but as soon as I tap the gas at all the tranny bites and moves the jeep forward. The lack of tranny noise, especially in low range, is nice compared to the manual trannies that I have experienced (with the exception of the ford toploader dad used to have).

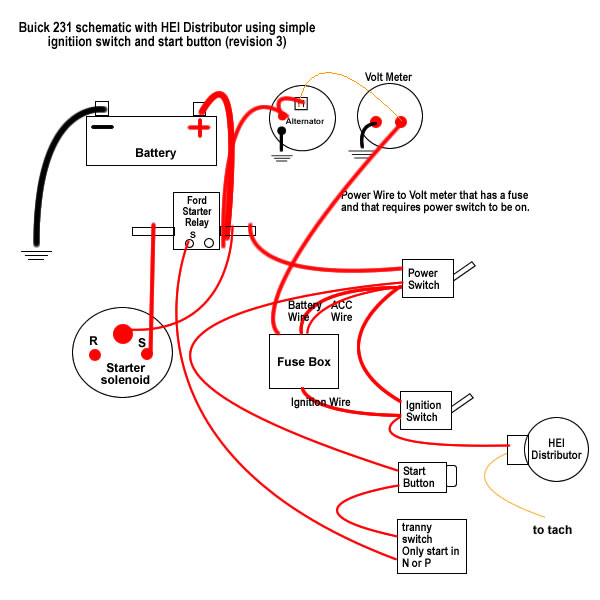

Brake Lights Fixed: I got the brake lights fixed; the lights work when the pedal is depressed now (as opposed to staying on when it wasn’t depressed). I used a brake pedal switch and assembly from a late 80s cherokee that had 6 wires coming out of it. I mistakenly wired the two wires that were ‘on’ when the brake wasn’t depressed. I just had to hunt for the two that were ‘on’ when the brake was depressed.

Power Steering Fluid Faux Pas: I learned today that if you accidently overfill the power steering fluid that it will pressurize and shoot out a tiny little hole in the cap, bounce off the ceiling in your garage, and shower stuff below. oops!!! Lesson learned. Truly, it was an honest mistake. I had taken off the cap to get out any remaining air and the fluid looked low. So I filled it up a little farther, put on the cap, shut off the engine and SURPRISE — a stream of fluid shot out the cap.

Some of the remaining fixes:

1. Fix turn signals- these don’t work at all

2. Fix small leak in brake fluid “T” at the front

3. Fix driver’s side head light wiring (something is crossed)

4. Build pattern for seat covers that I can send Jim (Thanks Jim!)

5. THE BIGGIE: Buy tubing for rollcage and build Cage (Steve, if I get Bisquit up there, can you still help me with this?)

6. Get glass and cowl seal for windshield.

7. Get Steering Wheel wrap and quick turn knob for steering wheel

[fb_button]