John’s complete the build of a 1955 M-38A1 USAF. Looks well done!

“My 1955 M38A1 is finished.

I bought it in late 2021 and has Dave Arnold (the area’s leading MV guy) go over it.

It had recently had an engine rebuild, so it was just the usual stuff as well as all new seals, radiator and wiring harness.

Wanting seatbelts, I wanted something period correct, so I used aircraft seat belts like the motor pool could have gotten from base supply. They were reconditioned by an aircraft supply store.

I also got an orange/white “flightline flag”, that vehicles had to display back then. The holder used an existing hole. Finally, there is a decal on the dash explained the control tower traffic signals; back then they used a light gun in place of a radio.

The power plug is operational and I bought a slave cable that is compare with airplanes (today’s planes use the same 24v plug). So when I’m at the airport, I could jumpstart aircraft.

Lacking a hood number, I put it in USAF Markings and made it from Larson AFB (Moses Lake, WA), and my dad’s unit circa ’55-57…the

62nd Troop Carrier Wing. I was born at Larson a couple of weeks before the Jeep was built.

The current Hood number is, in AF style:

55 (year contracted for),

K (Military vehicle, General Purpose),

82551 (Willys serial).

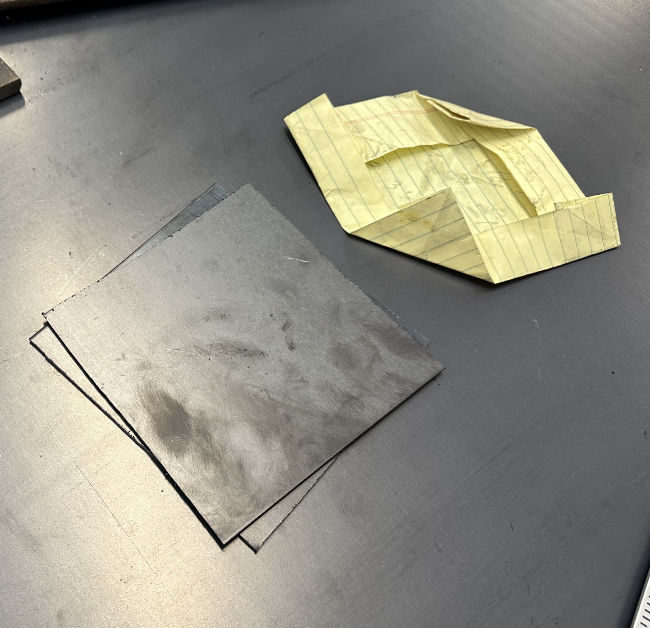

The paint is the PPG formula, (I fixed test shots of the other two and This looked best). Growing up in AF based and spending 20 years in myself, I knew what looked correct to me.

Since gloss finish shows body issues, I had some minor bodywork and final paint done by a pro body guy.

When our purchased, it was straight (except the back panel was pushed in a bit from a backing accident…we straightened it, but most of the damage was covered by the spare tire) with no rust except in the fuel tank well.”