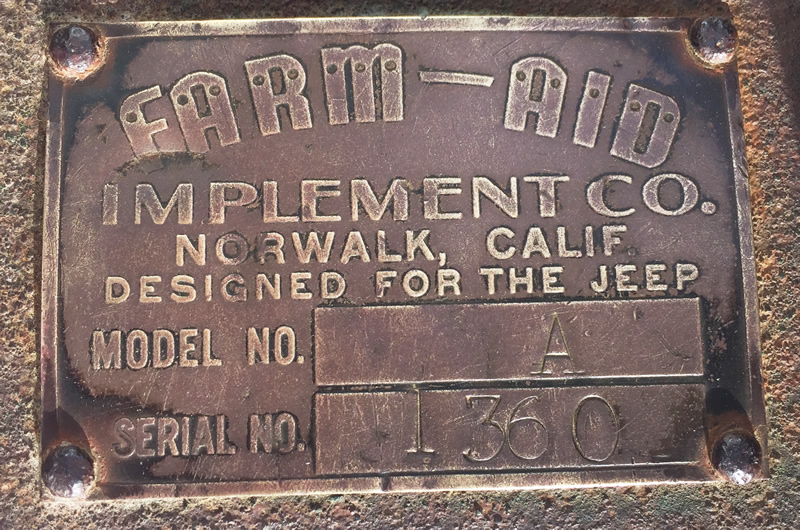

John Ittel bought this hydraulic lift a few months ago and has already restored it. This unit, sold through Mellen, began life on a 1948 CJ-2A from Northeast Washington State. The jeep and lift were barely used before the jeep and hydraulic unit were stored. There they sat for decades. Eventually, the lift was removed. Note that the green dual hydraulic piece shown was not a part of the system, but reportedly was installed on a different jeep that ran an extra large post hole digger installed on a 2A that operated in the Seattle area.

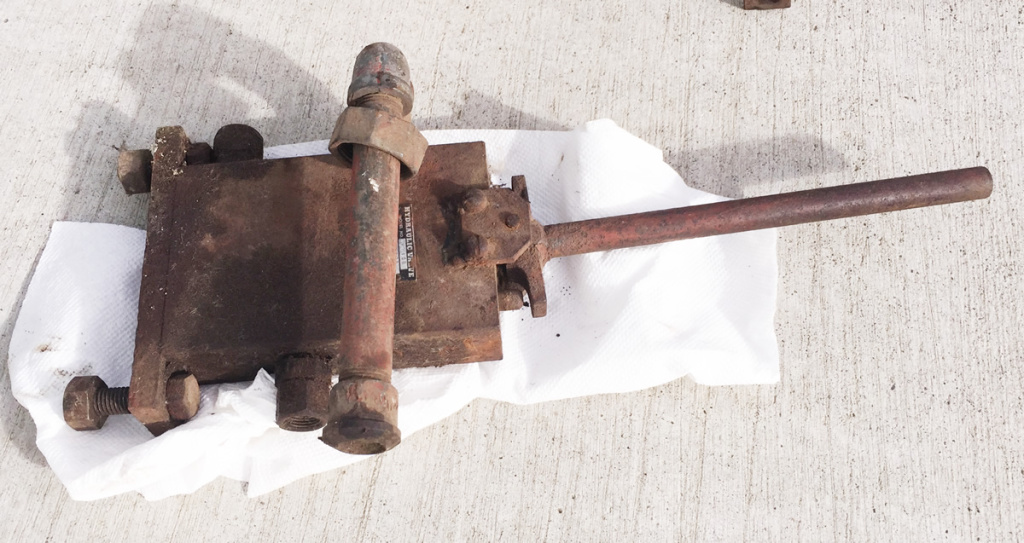

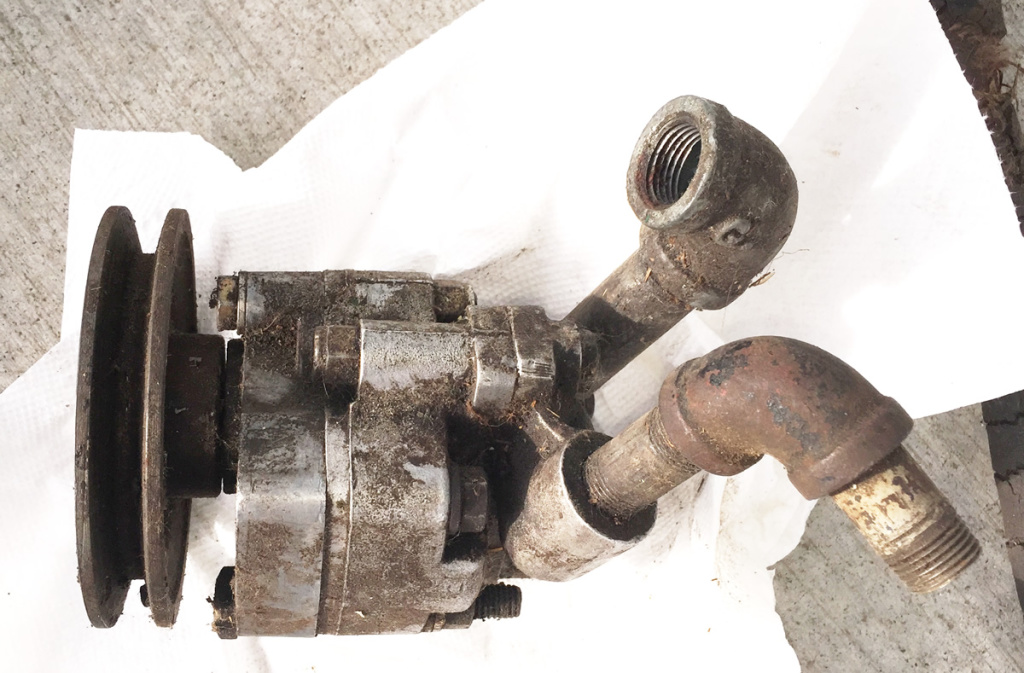

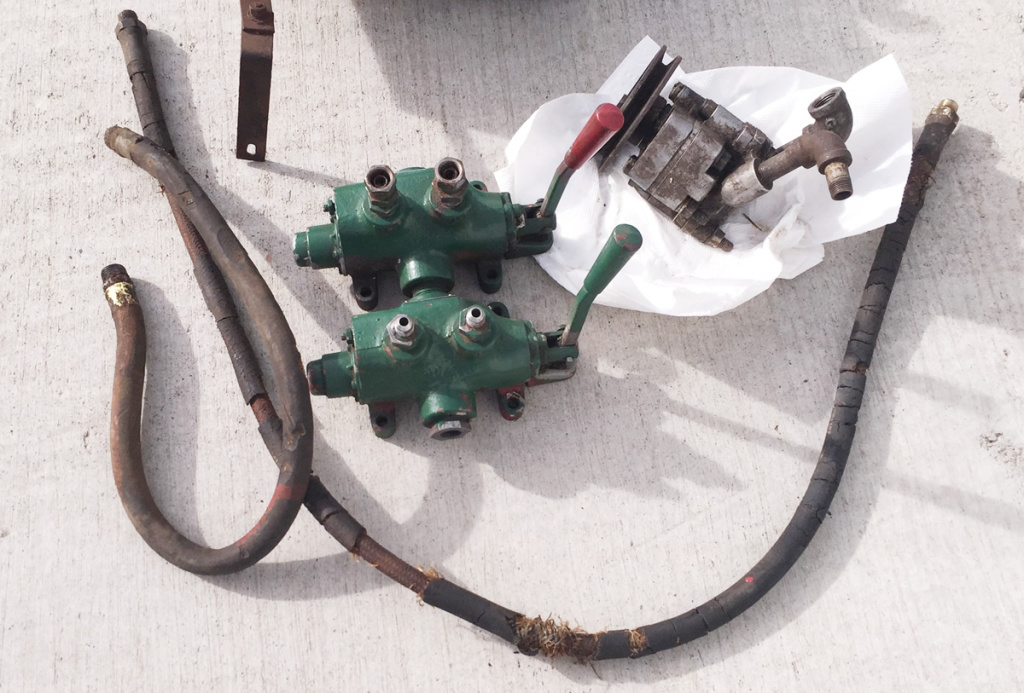

BEFORE RESTORATION (see more pics at the end of the post):

John provided details on the restoration:

I started the final mounting of the Farm Aid Lift. It is attached to a ’46 CJ2A. The rear unit mounts simply by using the existing bolt holes for the jeep draw bar.

The only problem was the two center bolts. This unit was designed without a consideration for using a PTO. I had to notch (cut off) one of the mounting holes on the lift because the PTO used this hole.

Since the hydraulic valve mounted between the seats I decided that rather than drilling holes in the floor for the hydraulic hoses I would run them along the floor and up through the firewall. The engine compartment is getting rather cramped.

Since the jeep has a Koeing crankshaft driven winch in the front I couldn’t use the crank to drive the hydraulic pump. I fabricated a bracket for the pump and strapped it to the generator. This is similar to the way a Hi-Low pump mounts.

The hydraulic reservoir is well designed.

–Unbolt the voltage regulator from the fender.

–Attach the tank to the fender using those holes.

–Mount the regulator to the tank by the provided tapped holes.

–Attach one tank bracket to the air cleaner bracket.

–Then attach the other to the battery hold down stud on the fender.

I had to have a new barrel made for the hydraulic cylinder because of severe pitting. I put in oil and fired up the jeep. Everything works.

Observations:

1. I see no way to mount any 3-Point tool (plow, post hole digger) to this unit.

It only extends about six inches beyond the rear bed of the jeep.

2. The hitch points are too high compared to other jeep hydraulic hitches.

3. There is no provision to bolt the front of the unit to the bed of the jeep.

4. Perhaps the only designed use is with the Mellon plow that is on your site.

After spending a few sleepless nights trying to figure out some good use for the Farm Aid I decided to make a little boom pole for it, but it only lifts about 18″. I can see why the previous owner removed it from his jeep.

The good news – This most likely is the only working Farm Aid Lift in the world, and is the fifth, now known, factory designed hitch along with Love, Monroe, Newgren and Stratton.

PRE-RESTORATION PICS:

What’s the implement, a crane?

Nice…It looks like a perfect set-up for moving ‘parts jeeps’ around…

That really is pretty cool. Funny that they made it non-standard for common three point implements. Maybe there was some kind of adaptor involved?

John,Very nice job on the restoration!

Bob, I was thinking the same thing,could be another part to make it work with three point equipment.Or possibly there were just a few implements that were designed to work with this lift only.Nice piece!

This is a puzzle. The way it lifts to keep the back four points plumb leads me to conclude there is more to this for a universal lift mechanism. I cant see being limited to just one manufacturer’s implements or they wouldnt sell to any farmer. If you think in terms of a quick-tach implement currently used on front-end loaders, think bale forks for example, it would allow the use of this lift for other implements. The six inches or so it lifts as measured at the bed would be magnified at the end of a typical implement. Given this is all flat stock, if you can just find a picture of something on another tractor or another jeep I dont think it would be difficult to duplicate the capability. I like it a lot and look forward to seeing what it can do once the mystery parts are located.

Another possibility, although it doesnt explain why there are four lift points, is that the two lower lift points could be the motive lift for traditional lift arms that would have been mounted at the ends of the draw bar. It actually looks like you have almost a foot of lift there, meaning at the ends of the traditional lift arms the lift would be much more like you would expect. That only leaves where the center-point would be. Were it not for the fact the hydraulic ram is mounted where it is at the aft end, I would think that an ideal location for the center adjustable top-link. But there is so much pulling force supported at the top-link that it would have to be much more substantial than what that ram is attached to. Im still thinking…

The Farm-Aid Lift is shown alternately along with the Hyteco Hydraulic Implement Lift in the Transport Motor Company literature seen here:

https://www.farmjeep.com/lifts/other-hydraulic-lifts/transport-motor-company-tmc-hydraulic-lift/

If you look closely at the implements attached to the Farm-Aid Lift, there really are no “3-Point’ implements attached to the Farm-Aid Lift. Most of the implements are of the “Tool Bar” type and the tool bar clamps to the lower structure of the Farm-Aid Lift. The only exception to this method seems to be the two plows that are shown. The one that shares some recognizable features of a 3-point hitch plow appears to have main beams welded directly to a flat face plate. That then pins to special brackets that clamp to the lower structure. There are additional special arms arranged in a triangle shape that extend from about the center of gravity point of the plow upwards and outwards to the upper structure of the Farm-Aid Lift. It is very specialized. The other plow, a Rogers TMC Plow, appears suspiciously the same as The Mellen “Jeep” Two-Way Hillside Plow and Ditcher. This plow is very similar in concept to an ultra rare single-bottom two-way trip plow used on Ford N-Series and Ferguson tractors, although the mounting is completely different on the tractor version.

Clint,

Thanks for the wonderful research on this! Great info!

Somehow, I didn’t see all of the document in the link you sent. That TMC body extension (next to last pag, middle pic) answers a question I’ve had about that style of body extension regarding who built it. I’ve documented that extension on jeeps, but never new the builder. I’ll add that to the extensions page.

– Dave

David,

Glad the link helped you on the TMC body extension.

I am in the process of doing a short article on plows for Barry and Evan’s farmjeep.com site. So, I could not help looking further into the Rogers-TMC plow and the Mellen “Jeep” Two-Way Hillside Plow and Ditcher. The two plows appear identical and they are both shown in use with the Farm-Aid Lift, but on second look, I don’t think they are very close to the rare Ford/Ferguson one that I mentioned. However I was able to find literature on a Dearborn model 10-14 Two-Way Plow that was sold for only two years and appears virtually identical to the Rogers and Mellen. It can be seen at the two links below:

https://i15.photobucket.com/albums/a379/ploughNman/TWOWAYBR01.jpg

https://www.ntractorclub.com/manuals/implements/plows/Dearborn%2010-14%20Two-Way%20Plow,%2010-85,%2086%20Plow%20Bottom%20w-alfalfa%20share%20(Temp.%20Parts%20List%2011-1-1948).pdf

I am convinced that the three plows were produced by the same company. I have yet to find who that company was. We know that most Dearborn implements were produced by other manufactures. They wore the Dearborn data plate, and in many instances, also wore the data plate of the actual manufacturer.

So with the Dearborn plow images in mind, I have a better understanding of of what we are seeing in the TMC and Mellen literature. It appears that the 3-point Lift Rogers/Mellen/Dearborn two-way plow is attached to the Farm-Aid Lift using the two lower link points on the plow. The upper link point of the plow appears to not be used for attachment to the Farm-Aid Lift. Instead, it appears that the upper part of the plow’s mast is clamped to the Lift structure.

The plot thickens.

Clint