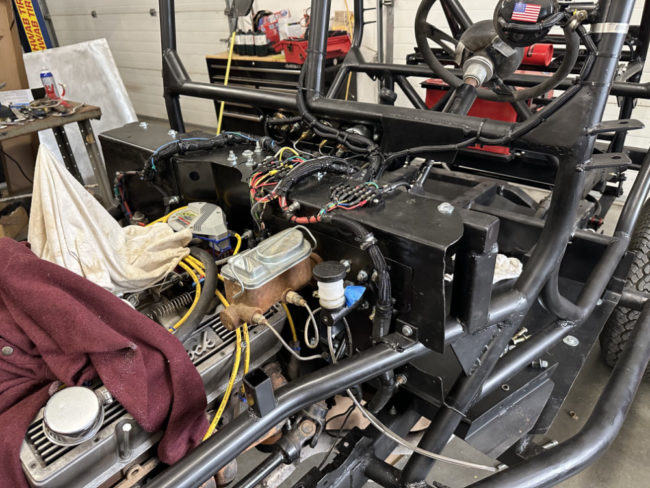

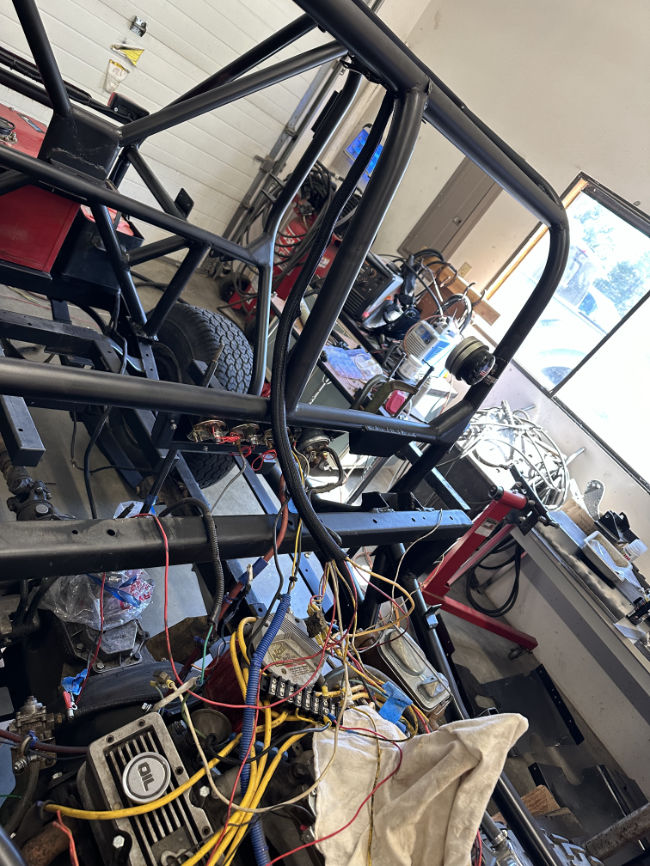

Progress continues on the FC, though if feels at a snails pace at times. I was near done running wires, but then decided to wire the main electric fan the correct way by installing a relay setup. I also decided to install the somewhat vintage Sun tachometer onto the left corner of the dash (in an existing hole), as it would be good to see the RPMs for when the transmission shifts. The brake lines, the speedometer cable, and all the wires from underneath the cab come up through two holes, so that should help clean up the look of the driver’s side.

I looked into solid state blinker setups, but haven’t found one that fits my needs. I may just go with the old school round flashers.

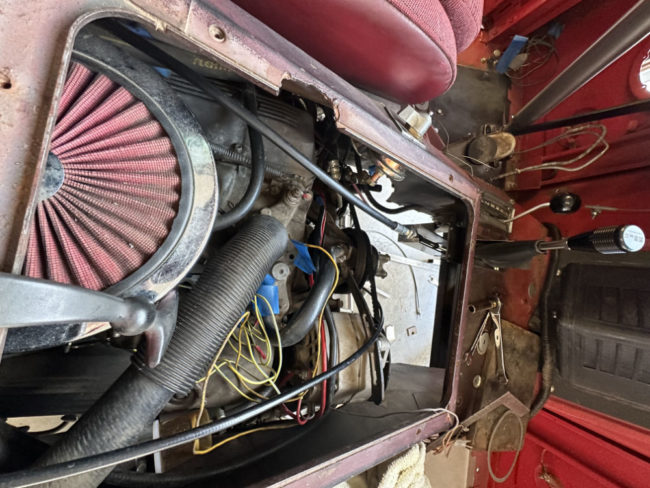

Here’s a pic of the dash. The spaghetti is laid in place to be cleaned up once all the wires are in their respective locations.

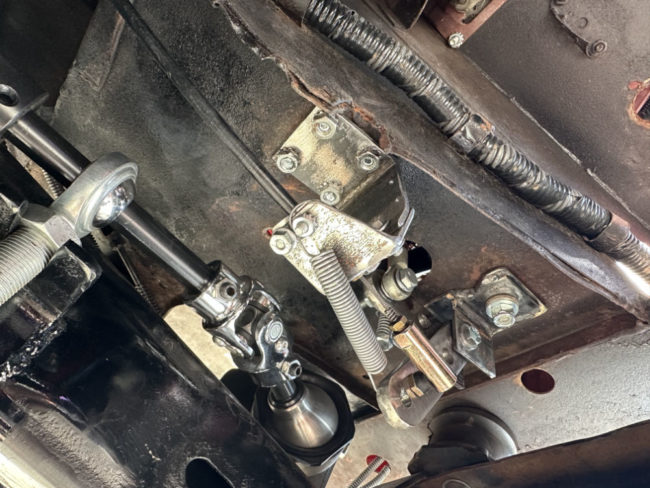

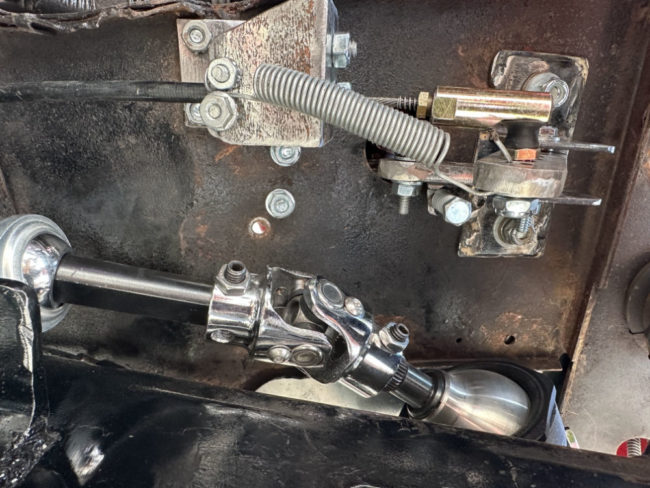

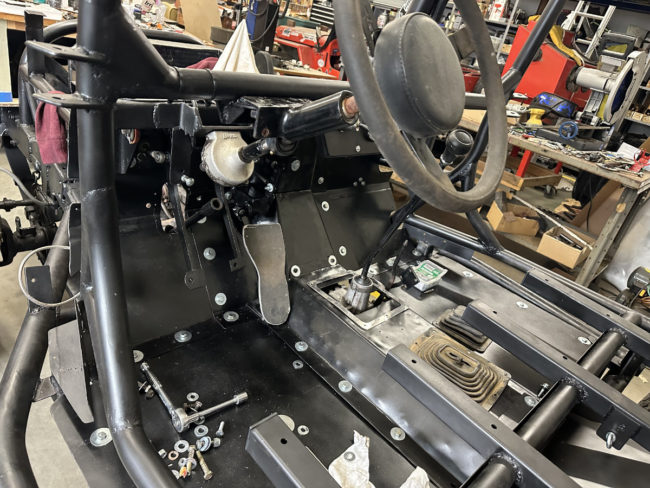

Below is the e-stopp parking brake installed, with the redone gas line just above it. I will be dropping that one high spot in the gas line, but, over all, I think this setup will work just fine. I’ve tried to leave space for the forthcoming mounting bracket for the rear cage & platform.

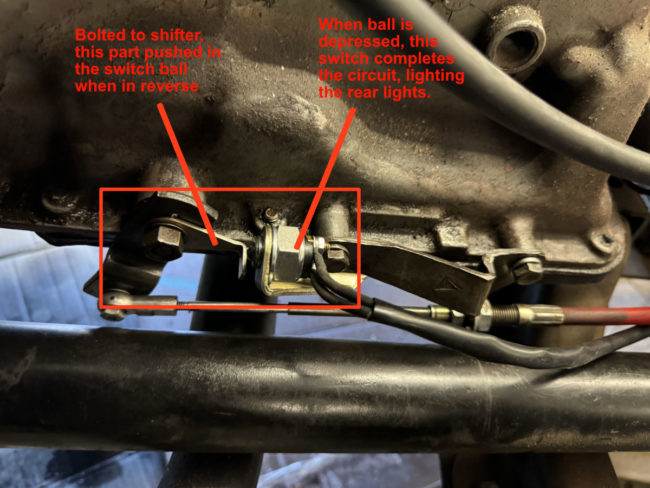

This phot shows the installed rear light switch, with the initiating bracket bolted to the shifter bracket. The wiring to/from the brake light still needs to be secured and won’t be laying on the front drive line as pictured! Everything fits well in there.

Finally, just for kicks, we finally mounted Ann’s sign. It looks great, though I think the “bunkhouse” should probably be renamed the “paint studio”, as Ann mostly uses it to work on her canvas paintings.