If you’ve never really looked at a map of Idaho, pull one out (or, I suppose you could use Google Maps). Between where I live in Boise and Coeur D’ Alene in the North is one significant route — US 95. Look to the East of US 95 and you’ll see National Forest after National Forest. Then look about halfway between in central Idaho and, if you look close, you’ll see the town of Kamiah. That’s where a reader named Randy and his boys, Devon and Dusty, call home. And, at their doorstep are endless National Forests they can explore with their friends. It is a regular jeeptopia.

Before you get to Randy’s story, keep in mind, that each of these jeeps started as basket cases, so there is still hope for your project! Also, a big thanks to Randy for taking the time to put together detailed descriptions of their rigs. Finally, check out the last pic … I think Biscuit would fit in just fine there :-).

Randy’s Blue 1946 CJ2A: This Jeep was purchased new by my wife’s grandfather in 1946 and was used for decades on the family farm. After her grandparents passed away we were able to purchase it from the estate for $200 in 1993; it was about $199 to much considering the shape it was in.

We completely rebuilt it from the ground up with a new steel tub and repaired fenders, grill and windshield. The tub is for an M38 but was all that we could locate at the time. I did most of the body work and my brother in law painted it in our garage. The motor, transmission and transfer case were all rebuilt and 11” brakes were installed, we also installed a rollbar, stereo, CB and a back seat.

I built a spare tire/gas can carrier/cooler rack on the back and we also have both a bikini and full soft top. I run 32×11.50 tires in the summer and fall; 33×12.50 tires in the spring when running in the snow for better flotation. The low range 2 wheel drive pill has been taken out of the transfer case and lock rights have been installed in both axles. A Warn M8000 winch was installed a few years ago.

Dusty’s Green 1946 CJ2A: I (Randy) purchased this Jeep for spare parts around the year 2000. It was a total basket case with a rusted up headless motor and most of the back of the tub missing.

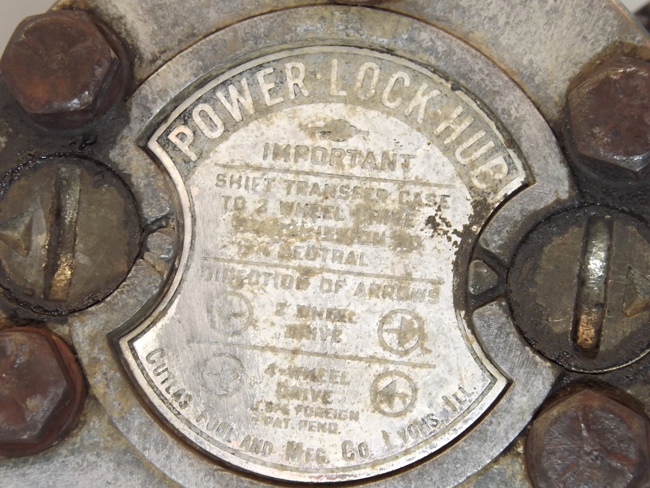

We decided to rebuild and modify it for my two sons to share; at the time Dusty was a sophomore in high school and Devon was in junior high. We started the project in November of 2004 and completed it for its first run on Memorial Day weekend of 2005. The 4 banger was removed and a Buick 231 V6 was put in its place, the T90, Dana 18 and stock axles were all refurbished and reinstalled as were 11” brakes.

New front and rear floorboards along with new wheel wells were welded in and we decided to take out what was left of the tailgate area and welded a flat back MB style back panel in its place. The lift is all from a spring over and we installed Saginaw power steering up front. Racing seats and harnesses along with a full rollcage were installed for safety and a rear seat was put in for passengers. A console contains a stereo and a CB is mounted to the front of it.

The tires and wheels are 35×14.50×15 TSL Boggers mounted on 15×12 Mickey Thompson wheels. I did all of the body work myself and my brother in law painted it Olive drab in our garage, a star was put on the hood just for fun. A Warn M8000 winch along with a winch mount and bumpers that we built ourselves were installed as well. The Jeep stayed pretty much this way for 5 years until after we found another Jeep for Devon that had bigger and better components than were in this one.

The tires and wheels are 35×14.50×15 TSL Boggers mounted on 15×12 Mickey Thompson wheels. I did all of the body work myself and my brother in law painted it Olive drab in our garage, a star was put on the hood just for fun. A Warn M8000 winch along with a winch mount and bumpers that we built ourselves were installed as well. The Jeep stayed pretty much this way for 5 years until after we found another Jeep for Devon that had bigger and better components than were in this one.

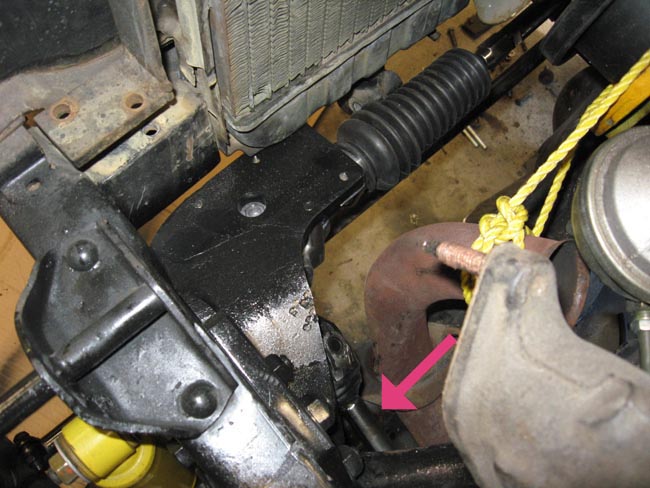

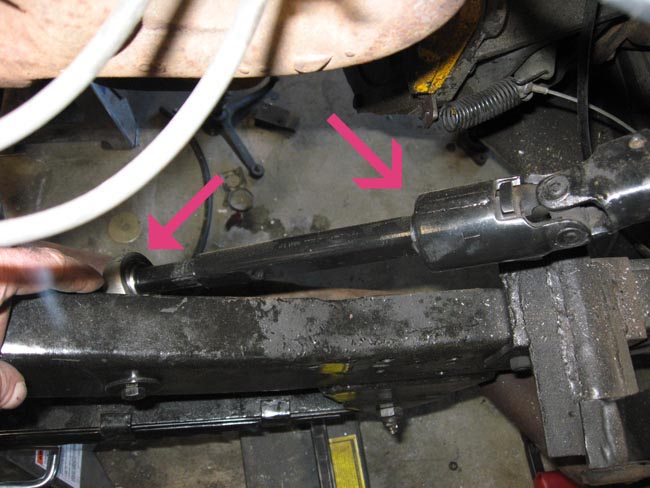

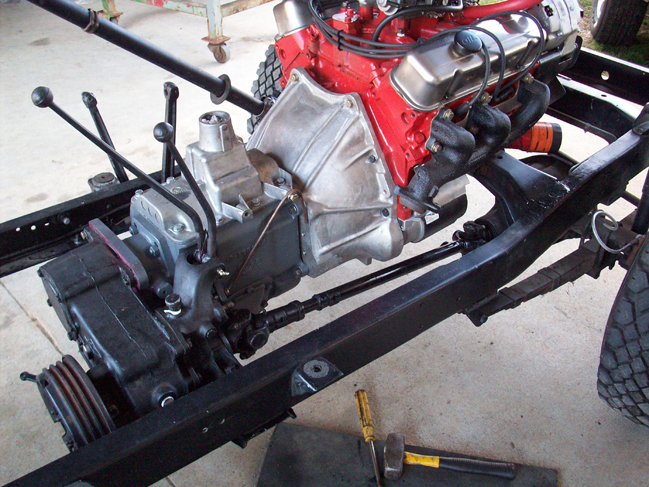

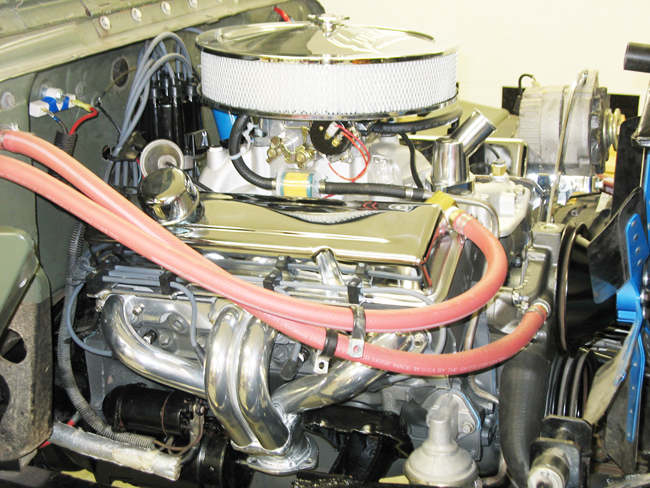

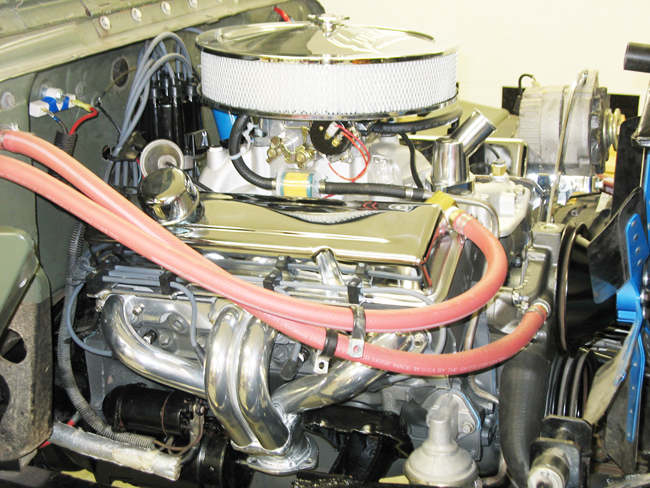

Once it became Dusty’s Jeep alone, he decide to box the frame and install a warmed up 350 Chevy with an sm465 transmission, Dana 20 transfer case that has been twin sticked and axles from 1975 CJ5. The axles are Dana 44 in the rear and Dana 30 in the front 3.73 gear ratios. New gears and ARB air lockers have also been installed in both ends in the past year. He currently has a set of wider Dana 44 axles to be installed some time in the future. Dusty did the entire drive train swap himself with only minor advice from me. He has since built a spare tire/gas can carrier/cooler rack for the back and plans on putting on a set of 40 inch tires after some fender trimming behind the back tires is done.

Devon’s Green 1942 MB: I purchased this Jeep off of E-bay for too much money but it already had the running gear that I was looking for which included a small block Chevy (283 not a 327 as advertised), sm420 transmission (no ceramic clutch as advertised), a twin sticked Dana 20 transfer case and Scout II axles; Dana 44 rear, Dana 30 front with 4.27 ratios.

The body was pretty rough and it had a thin skin of sheet metal installed all of the way around the tub that hid lots of holes and rust. A home built gas tank was in the back where a seat normally goes and a heavy spare tire carrier/cooler rack was mounted on the back. We started rebuilding this one on November of 2007 and had it mostly finished by Memorial Day weekend of 2008.

A warmed up 350 Chevy built to the same exact specs as Dusty’s was installed along with the refurbished running gear that came in the Jeep. All new spring hangers and reversed shackle mounts were built and welded on the outside of the frame in the front because of the wider Scout II axles, a new mount for the Saginaw power steering unit was installed and the frame rails were boxed.

The rollbar was cut apart and welded back together then installed in the correct place. The floor boards front and back were all replaced and the area between the rear fenders was increased by using narrower rear inner fender wells, as a result we were able to put in some comfortable small bucket seats. The rear fenders were opened up 2 inches and the rear axle was moved back an inch to make room for bigger tires.

The rollbar was cut apart and welded back together then installed in the correct place. The floor boards front and back were all replaced and the area between the rear fenders was increased by using narrower rear inner fender wells, as a result we were able to put in some comfortable small bucket seats. The rear fenders were opened up 2 inches and the rear axle was moved back an inch to make room for bigger tires.

Racing seats and harnesses were also installed in the front along with a stereo and CB radio. I had injured my shoulder during the winter and was dreading the thought of all of the sanding that would need to be done getting the body ready for paint when a friend of ours that owns a body shop (Orofino Body Shop) volunteered to do all of the body work and paint the Jeep as a graduation present for Devon; what a fantastic gift. We also had a star put on the hood and Devon built a rear bumper with a spare tire/gas can/cooler rack mounted on it.

A Warn M8000 winch was mounted on a winch plate and front bumper that Devon built as well. This winter he upgraded the axles to newer Scout II Dana 44’s in both ends with disc brakes in the front. We turned the front knuckles 15 degrees which gave it 6 degrees of caster and turned the back of the pumpkin up 9 degrees for a better drive line angle, new perches were welded on to get the angles correct. The axles now have 4.10 ratios with OX cable actuated lockers. He built a center console that houses the locker shifters and cutting brake handles for each rear brake. New shock mounts were welded on the axles and he built new shock hoops for the front, he added Bilstein 5150 shocks on both ends and a heavy duty tie rod and drag link set that is designed for Dana 60 axles was also installed, the tubing is 1.5 inch OD with .250 wall thickness and huge tie rod ends.

The tires and wheels are 13.50x37x15 TSL Boggers on Mickey Thompson wheels; 40 inch tires will be coming in the next year or two. All most all of the work done recently has been done by Devon, I helped him with turning the knuckles and installing the lockers but he did everything else himself.

Here are the boys Jeeps at the inlaws cabin in OroGrande which is near Elk City and Dixie as well. Every time the boys take their windshields off it rains, we got caught in a nice shower on this trip.

And, finally, this is a Jeep run with friends of ours that have cabins in the old mining town of Dixie (near Elk City) about 100 miles from Kamiah.