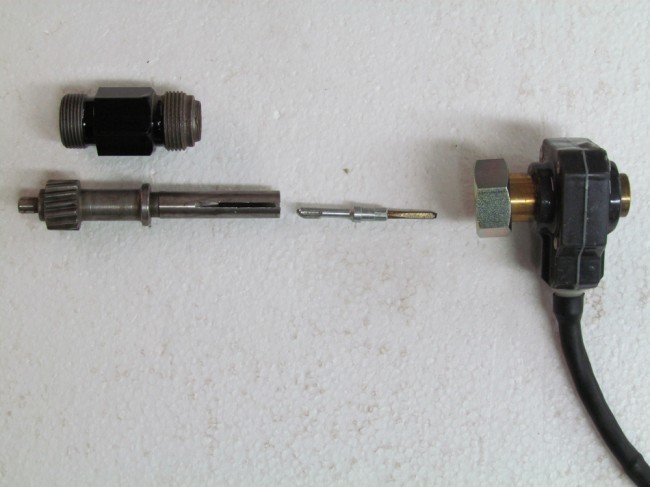

UPDATE: Paul forwarded a pic of the parts for the speedometer:

I’ve included a pic of Paul’s topside dash as an illustration of Paul’s dilemma/solution. You can read all of Paul’s adventures here.

Paul writes, “I recently hit a bit of a snag with the speedometer sending unit and I thought other Willys modifiers might be interested in the problem and solution. Since I repositioned the instrument panel above the windshield (the hard top will not be removed and the windshield is not a folding unit) I realized there would be a problem with the mechanical speedometer.

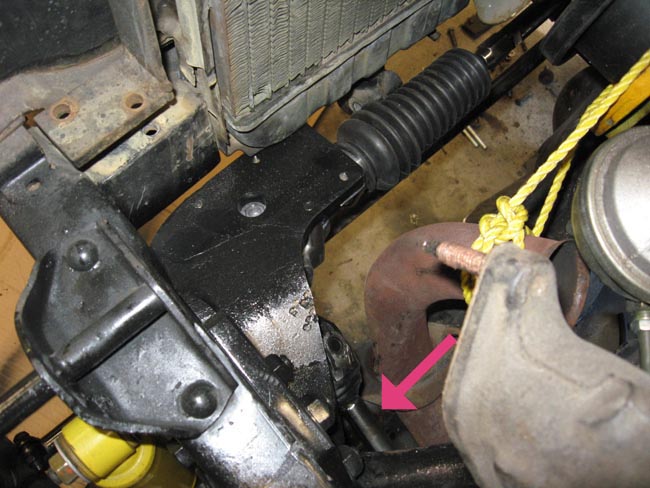

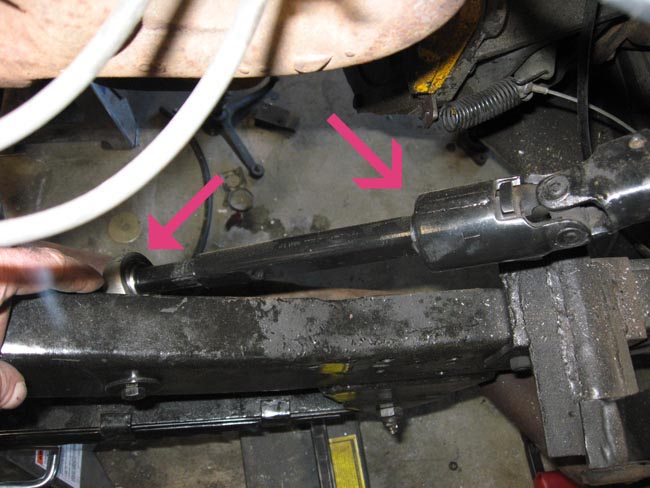

The speedometer drive cable would have to have many tight bends as it snaked it’s way from the rear of the speedometer, down the windshield post, behind the dash and under the body where it would screw into the drive unit on the transfercase. Taking into account the numerous tight bends, the length of the drive cable and the space necessary for the drive cable routing I figured it would be much easier to use an electric speedometer. This way I’d only have to string some wires from the speedometer to the sending unit (a hall effect device) attached to the drive gear in the transfercase.

Really rather simple but I discovered the original Willys speedo drive unit was made for a flanged drive cable and the electrical sending unit was made for a square drive cable. The stub cable supplied with the electrical sending unit is only two inches long but both ends are square so this wouldn’t work with the original shaft in the transfercase.

A friend of mine suggested I talk with the local marine diesel parts guys because he remembered the Detroit diesel engines used similar adapters as tach drives and they might have something which would work. Less than five minutes after I explained my adapter problem and showed the items I wanted to connect, Jim (the parts guy) found a two inch long flex shaft with a square drive on one end and a round, flanged end on the other. Not only was this the exact part I needed, the right length, and the right ends, but it was also the right price …FREE!

I realize most of the eWillys folks are keeping their Jeeps closer to stock when it comes to the instrument location, but it’s something to keep in mind if you do decide to go with an electrical speedometer. Jim sure saved me hours of work since I won’t have to build what I need; I believe a few dozen donuts delivered early in the morning are necessary as a special thanks. THANKS JIM !!!”