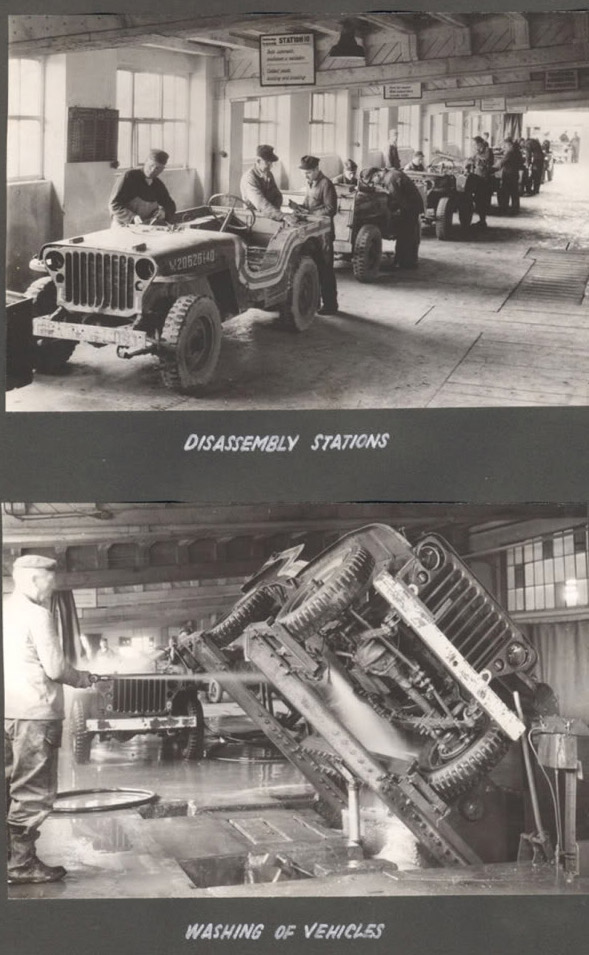

UPDATE II: Some additional photos of the Esslingen, Germany, recondition facility posted to Facebook. The first one is similar to the final photo in this post, but the details show it’s a different photo (probably earlier given these have soft tops and military markings.

UPDATE: This was originally published in 2013.

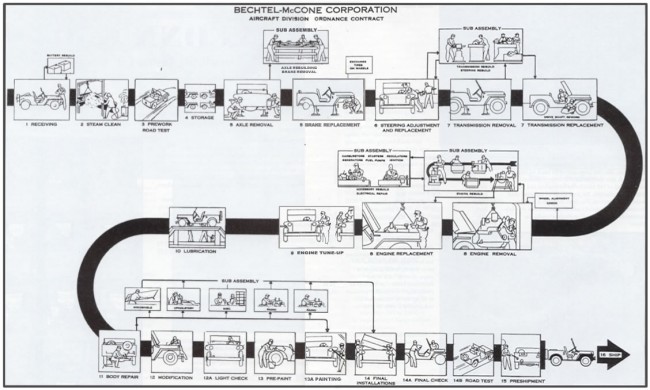

The Bechtel-McCone Remanufacturing Process rebuilt from an article in issue #122 of the Army Motors Magazine Winter ’08 by Lloyd White

One topic that appears in my new book is the 1941 attack on Russia by Hitler. Called operation Barbarossa and named for the medieval Holy Roman Emperor Frederick Barbarossa it was the largest invasion in the history of warfare. It included three million soldiers, 600,000 vehicles, and 750,000 horses. For comparison, the D-Day invasion force was approximately 150,000 men. Even a month later, only a million men had landed on the beaches of Normandy.

Supporting these huge numbers required plenty of logistics. For example, the German military had 250 companies of veterinarians that, at the height of the war, were capable of servicing almost 100,000 horses a day. Near the end of the war, horses became vital for the Germans on the Eastern front, as the terrain was often too inhospitable for vehicles, if they had any running vehicles at all.

What does this have to do with jeeps? Well, despite their disposable nature, many people don’t know that the U.S. Army’s Ordnance Department created special facilities to rebuild jeeps (and other vehicles). Facilities were located both in the U.S. and abroad. Here’s some information about the US divisions.

I spent time last night, probably too much, gathering and organizing some information about these programs. The idea and much of this information came from Maury Hurt’s efforts to gather and document reconditioning programs. There are a variety of threads about these at G503. However, what I didn’t see was a place that gathered the information together as I have below. I expect to add to this post over time with more information about the international programs.

UNITED STATES REMANUFACTURING:

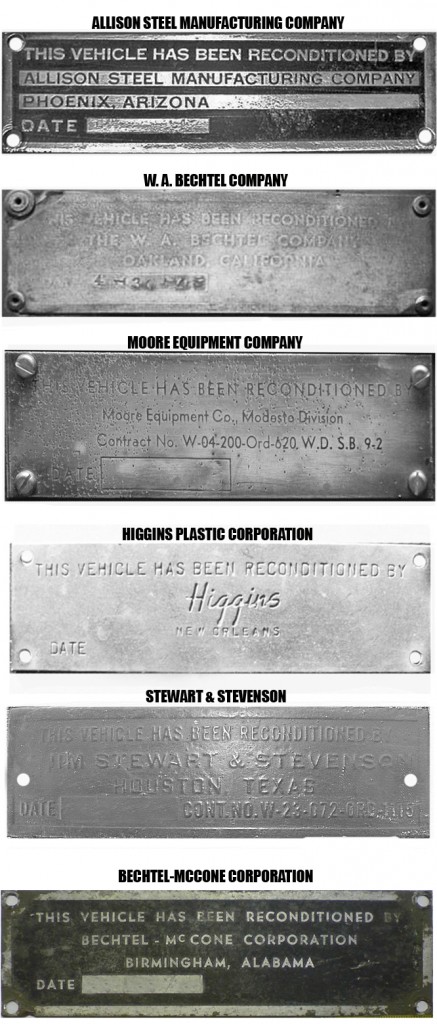

The following companies remanufactured a total of 16,176 jeeps in the United States according to Charlie Weaver via Jim Allen’s book “Jeep”. There are examples of the data plates applied to the dash of jeeps by the companies below. Unfortunately, I couldn’t find examples for all the companies. Next to the companies are the number of jeeps each is credited with rebuilding.

1. Bechtel McCone 4,986

2. Allison Steel Manufacturing Company Plate 2,865

3. Moore Equipment Co plate and a second one and a third one. 2,443

4. Higgins Plastic Corp 1,850

5. Stewart & Stevenson 1,750

6. W.A. Bechtel plate 1,555

7. Bishop McCormick & Bishop (no examples found) 343

8. International Diesel (no examples found) 267

9. Vancura Motor Company (no examples found) 66

10. A.M. Meyerstein (no examples found) 49

I found these plates in several locations (documented in the links above) and then organized them as you see. I thought it would help people who run into plates, but don’t know what they have.

EUROPEAN FACILITIES:

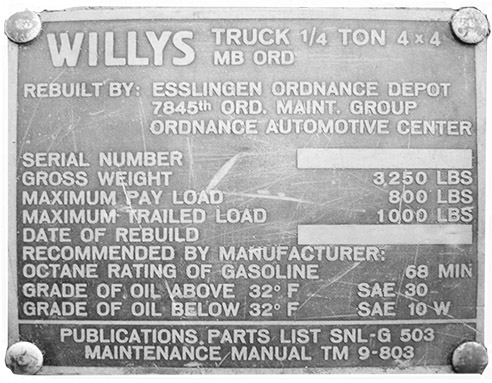

Internationally, there are two great links I can recommend. The USAGermany.com website has a list of Ordnance facilities, some of which serviced jeeps (maybe all?). Another good link shows the Esslingen Ordnance Rebuild Shop’s booklet posted by Maury celebrating the 10,000th jeep. You will have to login into the G503 site to see it.

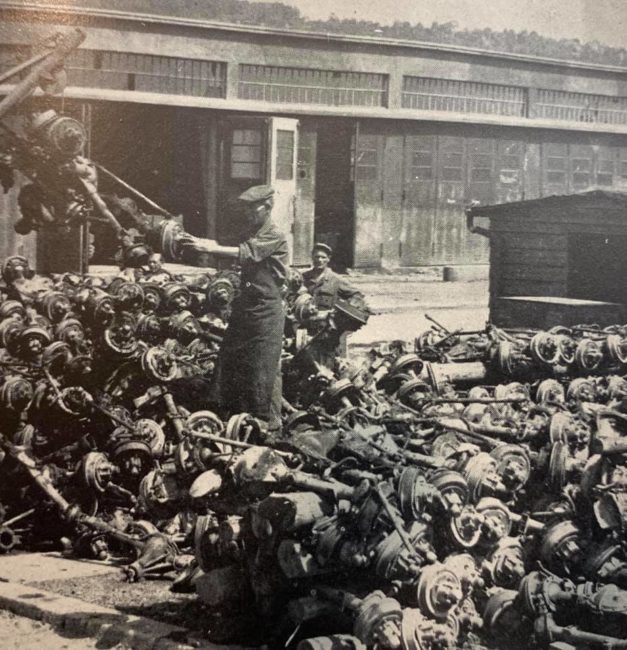

The picture below shows a line of Constabulary Jeeps ready for rebuilding.

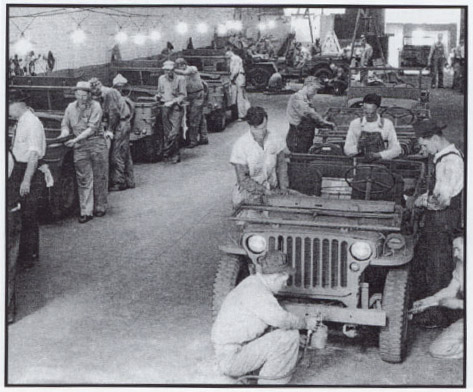

Here are jeeps in process at the Esslingen facility.

While the US remanufacturing facilities were shut down at the end of WW2, shops like the Esslingen facility weren’t launched until 1946. During the first few months they could only do around thirty jeeps a month, partly due to a shortage of parts, water, and electricity. Once they moved into new facilities they reached over 400 jeeps a month by 1948. In the picture below, you can see that lots of these refurbished jeeps came with tops.

Here are additional links to explore:

http://www.earlycj5.net/forums/showthread.php?46768-WW-II-Reconditioning-Program

http://www.jeffcohistory.com/newsletter_apr_12_pg4.html

There are stories in Google Books which describe stories about the Ordnance Men at work:

Here’a pro war Ad from Willys Overland that you probably have seen other places

Here are some men working in Japan

Ordnance men created a jeep sedan out of spare parts

A Veteran of the Ordnance Department shares his story

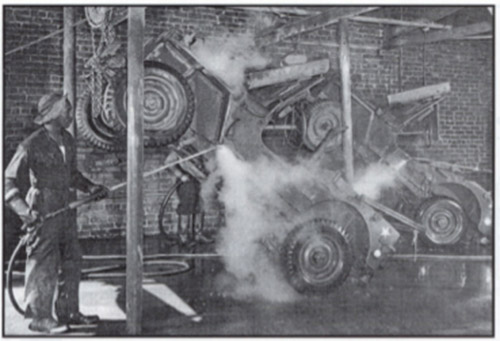

That’s very cool. I love the Jeep washing stations!

Rebuilding continued especially with the more costly vehicles and different from the WWII era the installations were Army, not civilian companies. In Vietnam (46th Eng, A Co) I had a M56 Contact Truck with a 1950s era depot level rebuild tag, I think it was a fort something or other in the heartland, like Kansas or Nebraska. I questioned at that time and an older sergeant, he said civilians manned the depot rebuild shops. I somewhere in a box have a tag for my M38, a rebuild tag; it too was a US Army installation. Anniston Army Ordnance Depot, Alabama rebuilt M38A1s, but most of their stuff was heavier armor. I is interesting to see some press given to this subject, I’ll bet there are some stories to be told.

One of the guest speakers at a Midwest Willys reunion did his presentation on a Jeep remanufacturing company. Can’t remember the name off hand but it was very interesting.

Dave –

1. My dad has one of these Jeeps – or more accurately stated, his otherwise mystery Jeep MB/CJ has one of these dash plates, but no serial plate. I’ll send you a picture next time I’m home.

b. The presentation may have been from a guy on the earlyCJ5.com forum named Adam Sparks. He sent me some info; I have a message into him.

My jeep has a data tag that says rebuilt by Esslingen Ordnance Depot 7845th Ord. Maint. Group 4/6/1952. It appears to have an MB frame and an MB body. the s/n is J211678 and the engine is MB 301352. 935 is stamped in the body above each rear wheel. I bought it in Texas and it has a Blue department of defense Id sticker on the front bumper that says Dyess AFB. Research indicates this type of sticker was used for base access at one time. That is about all I know so far. I am having the transmison rebuilt and it is in storage for the winter. Thanks for this post.

I have remanufactured JEEPS from the British (REME) and Greek military. The Greek JEEP has a rebuild tag on the engine block from an earlier rebuild at Karlsfeld Ordinance depot. Both JEEPS were essentially new vehicles when I bought them. I could not remember the issue of Army Motors issue Lloyd’s excellent article was published and appreciate seeing it here.

http://www.mulliganmotorpool.com/mb_103405_home.html

http://www.mulliganmotorpool.com/gpw_158029_home.html

Jim, the Greek names carved in the steering wheel are pretty cool! I’d have to drive that jeep by the spokes!

Hi Dave,

Dan, scramboleer, tracked me down, here in the Philippines, via e-mail.

You can use any of the information that I collected for my presentation at the Fall Midwest Willys Jeep Reunion. I can’t locate any of it at the moment, on a back-up disk somewhere, probably back in the States. However, Dan has the information.

I’m glad to see interest in this resurfacing again.

Be sure to tell Doc Kayser about this, he’s the one who asked me to research the program and put together the presentation on it.

cheers!

Sparky

Thanks Sparky. I’ll email Dan right now.

– Dave

ten years ago I acquired a parts DUKW. The engine had a rebuild tag on it, having been rebuilt by BMW after the war.

A 44′ gpw in California you posted on January 30th had the esslingen rebuild tag I believe….Dave I have sent you a pic of the glovebox door.

My ’42 GPW (I purchased locally in 1969) has a Bechtel/Oakland rebuild tag…I wish I knew the story of how it got from California to Vermont.

It looks like all the rebuild tags were about the same size.I will have to look closer at my GPW dash to see if it ever had holes for a rebuild tag.On a rebuild note,the engine that was with my GPW when I bought it had a French rebuild tag on it.I will try and send a pic to you when I can Dave.

AOD, (Anniston Ordnance Depot) is a military run facility, but manned by civil service employees. From the beginnings in September of 1941 there were four employees, by November of 1941 the head count was at 4,339. This workforce mainly produced munitions. In 1950, AOD’s mission expanded to include maintenance, overhaul, and repair of combat vehicles. Vehicles included are M19, M38, M42, M47, M48, M56, and M59. In 1962, AOD is placed under jurisdiction of the Army Material Command, and the name was changed to ANAD, (Anniston Army Depot). (ANAD website)

Bechtel-McCone, located in Birmingham, AL, was positioned at the southern part of what is now the Birmingham-Shuttlesworth Airport. Some of the buildings are still standing today. Their scope of work included modifying or up fitting production aircraft to meet the designated unit’s needs. Forty percent of the workforce was made up of women. The Aircraft was the main business, but a crew of 600 people with “only moderate levels of skill”, restored battle fatigued Jeeps. (Jefferson County Historical Association)

Thanks GMWillys. I emailed the Jefferson County folks as work will send me to Birmingham in a few months. It would be cool to see any info they have on the Bechtel-McCone refurbishment process, if anything. My dad would get a kick out of it. His Jeep was reconditioned there on 2-1-1945.

Dan,

The article containing the information posted, is as follows;

http://www.jeffcohistory.com/newsletter_apr_12_pg4.html

The Southern Museum of Flight should have some information on Bechtel-McCone;

http://www.southernmuseumofflight.org

The best source of information will be at the U.S. Veterans Memorial Museum in Huntsville AL. They keep a collection of Military Jeeps from prototypes through M151A2s. It is a small museum, but there is a research library, and knowledgeable caretakers on sight. I’m sure they would have all the information available that you seek. Huntsville is about an hours drive from Birmingham.

http://www.memorialmuseum.org

Thanks for the links and additional info. It’s always so helpful to have!

I have recently bought a 1942 MB with a brass data plate DOD 3/23/1942, number 129928(BRT) that has a complete Willys chassis and a complete GPW body. The rebuilder is Moore Equipment Co out of Modesto, CA, and their tag is dated 6/45. Tranny and transfer case are also Moore rebuilds.

Thanks for the update Tony. It’s great to track these. I hope you are enjoying it!

– Dave

@ Tony,

Does your MB has a MB serial number? Maybe it is original The first GPW’s were build on a MB frame

I own a 1942 GPW , a script body on a MB frame with GPW serial number (GPW4141) .

It has also Moore Equipment Co tags. One on the dash and one on the front axle dd 7-1945.

It was used by the Greek army until the late seventies and is has also Greek names carved in the steering wheel

Thanks for posting those recently “discovered” photos, Dave!

Here’s an updated link in case anyone would like to see the entire book that was published at Esslingen to celebrate their 10,000th rebuilt jeep:

https://forums.g503.com/viewtopic.php?f=85&t=147492&hilit=esslingen

Thanks Maury!

J=E=E=P…R=E=C=O=N=D=I=T=I=O=N=I=N=G … THE STORY OF MY LIFE

More pictures of the Esslingen rebuild plant at:

https://forums.g503.com/viewtopic.php?f=85&t=147492

Thanks John!