If you haven’t yet read about Pauls M-38 project, go to installment 1 and installment 2.

Paul, take it away …

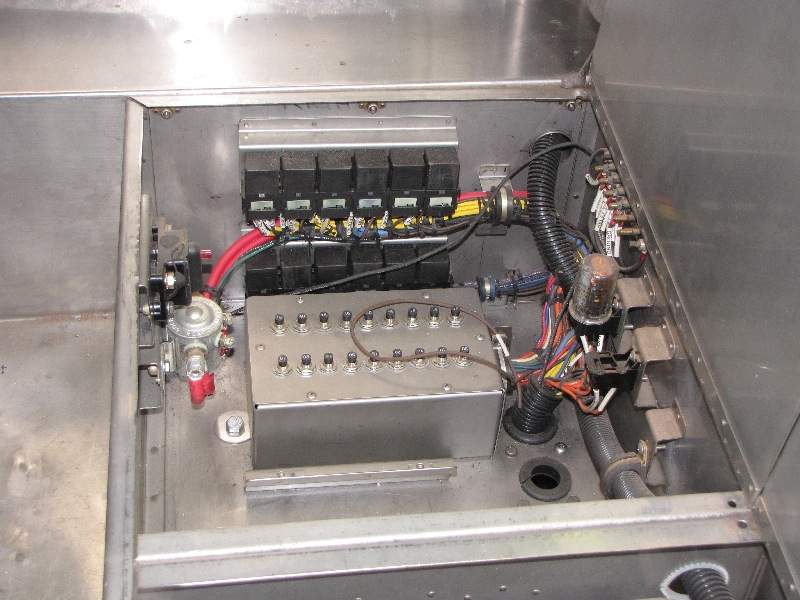

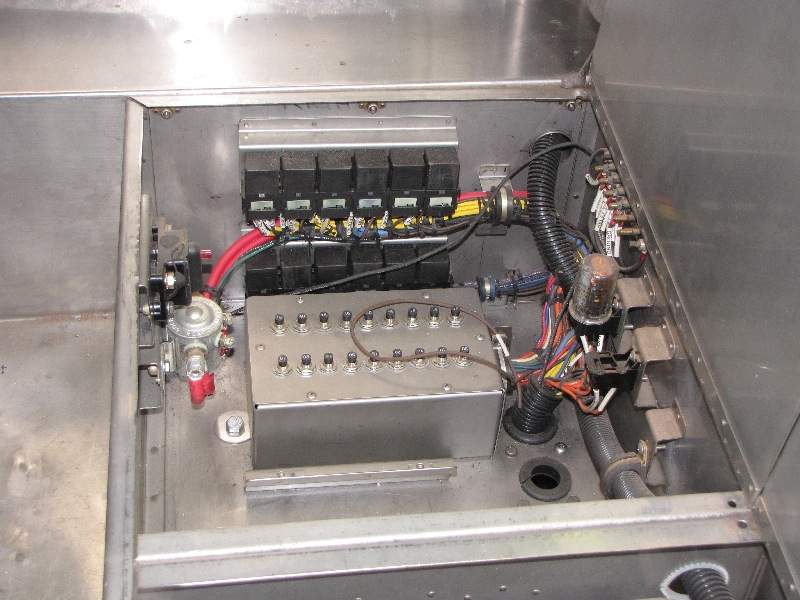

Paul Bierman again with a few more pictures of the never ending Willys project. I didn’t want a rear seat (Who can fit back there anyway?) so I fabricated a storage box which spans between the rear wheel wells and is divided into two sections. The half behind the passengers seat is the new battery location along with the circuit breaker panel, the master relay and circuit breaker and most of the switch relays. The half behind the driver’s side is the home of a now vintage (but it’s still brand new, I bought it quite a while ago) ten disc cd changer with some room left over for an out of view storage compartment. I’ve replaced just about all of the wiring with new (there’s some original wiring on the gas heater still but I’ll get to that sometime) with some fancy pants, super flexible cold weather wiring which stays flexible down to 55 below zero F. Boy, doesn’t that just make you feel dandy. If it’s that cold I’ll wait till spring, besides I try to draw the line on outside work when the temperature drops past 40 below zero F, nothing’s worse than having to take a leak when you’re wearing multiple layers of clothing eight inches thick and Little Mr. Wizzard shrunk up to an inch and a half. No matter what you do you know at least one of your boots is going to get wet.

Moving the instrument panel above the windshield caused still more problems but the most annoying one was how I could get all the wires from the gauges down to the main body without my work looking like crap. I was at work thinking this over (Ok, I was in the bathroom but I do my deepest thinking sitting down) when I happened to glance over at the wall and saw a beautiful stainless steel handle just the right size with curved ends, satin finished and everything! Problem solved, until I mentioned this great solution to my boss and his exact response was, “Touch it and die.” Geeze, guess I’ll have to spend my own money and purchase some handicap grab handles. The local home supply store had quite a selection of stainless handles but I ran into a problem with an over enthusiastic clerk wanting to help me with my bathroom remodel. He’d never heard of a 52 Willys bathroom renovation. The handles worked out great, you can see them on the pictures of the windshield/instrument panel photos by the door posts.

Winter was late getting here (I love global warming!) but I have lots of cold dark days ahead of me so the Willys will get a great deal of attention before this latest batch of snow melts. Next week I’ll have the side and rear window glass cut and then I’ll have to make patterns for the door window glass and they’ll be ordered when my wallet says it’s ok.

PS … I’ve really enjoyed the comments left by fellow Willys wackos, the concern about welding above the jerry can was nice but the can had never been used and I threw it out after I’d made the gas can mount. If I was to worry about welding safety I should have thought about the beef and bean burrito (with cheese and onions on top) I’d eaten for lunch, not so much for the flamability aspect (the poor garage just isn’t that tightly sealed) but the thrust developed after lunch could have blown me off those fancy bucket workstands!

1956 Willys jeep CJ5. Fiberglass tub, all else metal. Buick 232 V6, runs good four wheel drive works good. Needs seat belts and side mirrors to be street legal”

1956 Willys jeep CJ5. Fiberglass tub, all else metal. Buick 232 V6, runs good four wheel drive works good. Needs seat belts and side mirrors to be street legal”

I have a 1948 Jeep Willys, it has a full roll cage soft top and bikini top included, tow bar, the tub is in good shape all it needs is a motor, it had a 350 in it, still has a munsy 4 speed. We have out first baby on the way and would be willing to trade for a family vehicle of the same value. if not 1500 cash OBO will do. please call for any questions. 209-781-0598 Cole.”

I have a 1948 Jeep Willys, it has a full roll cage soft top and bikini top included, tow bar, the tub is in good shape all it needs is a motor, it had a 350 in it, still has a munsy 4 speed. We have out first baby on the way and would be willing to trade for a family vehicle of the same value. if not 1500 cash OBO will do. please call for any questions. 209-781-0598 Cole.”

Newest daughter just arrived and Jeep has to go. Great vehicle but not a family cruiser. Collector or workhorse, your choice. Comes with 6′ Meyers plow. Runs and operates fine. Homemade soft top. Open to trades for newer Wrangler or CJ otherwise $2725″

Newest daughter just arrived and Jeep has to go. Great vehicle but not a family cruiser. Collector or workhorse, your choice. Comes with 6′ Meyers plow. Runs and operates fine. Homemade soft top. Open to trades for newer Wrangler or CJ otherwise $2725″

1964 Willy’s Jeep. Has not been operated since 1990. In fair shape. A Great Restoration Project or for Parts. I can email any interested party additional pictures. Comes with the snow plow attached. We cannot provide the title (it has been lost), but do have a New York State Registration document for this vehicle. Additionally, we cannot provide a key to the ignition. This car is sold as is. It must be picked up or buyer must arrange pickup. Feel free to email me with any questions.”

1964 Willy’s Jeep. Has not been operated since 1990. In fair shape. A Great Restoration Project or for Parts. I can email any interested party additional pictures. Comes with the snow plow attached. We cannot provide the title (it has been lost), but do have a New York State Registration document for this vehicle. Additionally, we cannot provide a key to the ignition. This car is sold as is. It must be picked up or buyer must arrange pickup. Feel free to email me with any questions.”