Nice press photo of a BRC-40 climbing a hill.

“Original 8″ x 10″ glossy press photo. Hand written on back : ARMY ARMORED SCOUT COMMAND CAR PEEPS. Dated May 4, ’41. Good condition for its age.”

Nice press photo of a BRC-40 climbing a hill.

“Original 8″ x 10″ glossy press photo. Hand written on back : ARMY ARMORED SCOUT COMMAND CAR PEEPS. Dated May 4, ’41. Good condition for its age.”

Lots of great details about the build included within the description.

View all the information on eBay

” This is an Arizona titled (clean and clear) 1949 Willys Pickup built on a stretched 1997 Jeep Wrangler frame with a three-link front, 4-link rear, one-ton axles, manual transmission, 505 cubic inch Dodge/Chrysler RB Big Block engine. There are many many details that went into this build and I will try to list them here, but may miss some or forget some. Any really interested parties need to come see this truck first hand and ask questions. I reserve the right to cancel the auction any time in case of local sale, or if I decide to keep the truck. The truck drives great on-road and is extremely capable off-road. It has plenty of power, and turns heads everywhere it goes. Everyone loves it from Rednecks, to Hippies, and everyone in between.

Built as a Jp Magazine project Vehicle there are 8 or 9 3-4 page articles on the build. To see them Google: “Jp Magazine Wicked Willys”

You can also Google “Wicked Willys Ultimate Adventure” for more info on the truck and the UA trip

The truck, since I finished it in june of last year, has been on Petersen’s 4-Wheel & Off-Road Ultimate Adventure for 2016 (that included about 2000 miles of on road and trail driving) Over the Rubicon, Isham trail near Trona, CA, and part of Fordyce. Its also been on a few trails in AZ and all over Moab during Easter Jeep Safari 2017. It drives over almost anything the driver aims it at and is very stable off-road. I’d love to keep it, but I like to build 4x4s and can’t keep them all.

Continue reading

After fixing some wiring and correcting the clutch cable length, I was able to take Patterson down the street and back. Brakes worked, clutch worked, and it felt like there was plenty of power. However, it’s definitely running rich, so we’ll tackle that tomorrow, along with improving the timing.

Rob won these old club jacket patches and didn’t have a use for them, so he gave them to me. Given the art, I’d guess these (I have two patches) were produced in the 1970s or earlier. Sumner is a city about an hour south of Seattle. They are a laying on Patterson’s driver’s side fender, so that gives you a sense of their size. What great vintage jeep art they are.

This photo provides a good look at how frayed some of the wire was behind the speedometer. Worse, this wiring was sitting on the metal brace!! in the background is the volt-a-drop which provides stepped down voltage to the King Seeley speedometer).

Electrical Mess:

We’ve been working hard on Patterson the last couple of days. Most of our time has been consumed with checking wiring and rewiring stuff. Between frayed wires and mis-wired stuff, it’s filled our time. Apart from the types of frayed wire seen in the pic above, I discovered 1) the wires to the amp gauge and light were wired into the oil light (fortunately, all I had to do was pop out the light and plug it into the amp light), 2) the amp light was missing altogether (thankfully I could steal one off of Rusty’s speedometer), 3) the ignition jumper that screws to the back of the speedometer was laying on the metal brace (must have caused some shorting), 4) the oil light wire was wired to the fuel gauge (which explains in part why the fuel gauge didn’t work … well that and there was no wire connected to the fuel tank wire.

Dimmer Switch:

The dimmer switch has been lubed, reassembled, de-painted, and installed.

The Horn Wire

Patterson came with a button attached to the side of the steering column that was used as a horn, but it didn’t work. Since we were already changing some of the wiring around, we decided to steal the column shift button wiring from Rusty’s steering column I wired last month and use it on Patterson.

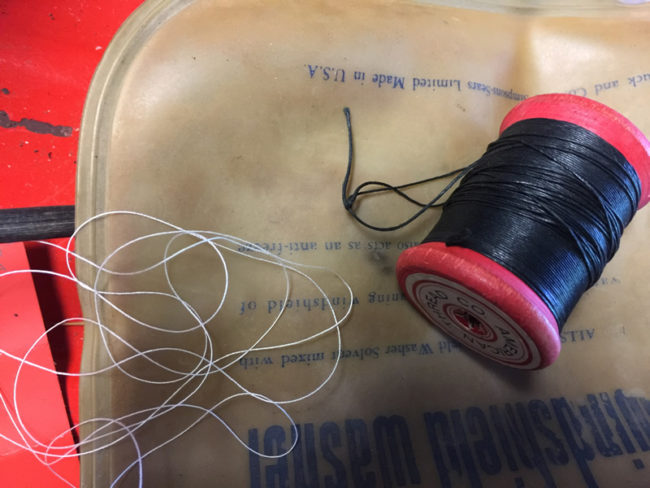

To start, I knew we had to run some non-electric wire (similar to bailing wiring) through the length of the column in order to pull the horn button’s electric wire down the shaft. That sounded like a good idea, but several attempts at pushing the wire up the column were a failure: the wire kept getting snagged as I pushed it up the column. I was getting frustrated.

But then, my genius wife had an idea. Why not blow some thread down the column using an air compressor nozzle. Once the thread came out the bottom, we could pull the bailing-like wire back through. I admit, at first I thought it sounded a little crazy. After all, near the bottom of the column shaft it narrows, so I thought for sure the thread would be stopped by it. But, then I took a breath and thought …. hmmm … what could it hurt to try?

Sure enough, she produced some thread, dropped a little down the column, then stuck the air nozzle into the hole. That thread blew threw the bottom of the column in a couple seconds. It was genius! Well, almost genius, as we had to upgrade our thread to thicker thread. Other than that, we had the column horn working in no time!

This is the thin thread we tried. It didn’t she enough tensile strength to pull up the wire. She just dropped some thread in and the air blew the rest of the thread down through that small hole at the bottom.

Once we shifted to the thicker, black thread it worked perfectly.

Ted Jordan shared these photos showing a comparison between Dumas and Carson center seats. In the photo below, the Carson seat is shown on the left and the Dumas on the right.

Help us out by buying an Alaska Or Rust T-shirt. They are now available for sale. They are 100% heavy cotton and are priced at $25 from the Alaska Or Rust site (to cover shipping**) or $20 in person. You can use paypal or use a credit card. If you’d prefer to send a check (or have questions), email me at d@ewillys.com.

http://www.deilers.com/AlaskaOrRust/shop/

Most of our shirt sizes are XL and L, but we have some XXL, M, and a handful of Smalls.

**If you live outside of the US or Canada, we may have to charge extra for shipping.

Thanks to Kevin for sharing these photos from Cranesville Auto in Amsterdam, New York. Inside the jeep there are red, white and blue flowers planted, too.

The machine shown below was used to thaw front axles, among other things I’m sure. It was published in the January 1947 issue of Popular Mechanics.

Last week when we were in Renton, we tested Patterson’s headlights and discovered the foot-based dimmer switch wasn’t always working correctly. After a little research, I discovered the CJ-3A page had a useful thread on the topic, but naturally the switch demonstrated wasn’t exactly like the DJ-3A switch. The one shown on the CJ-3A page had a square end, while the DJ (and I’m assuming others of the same vintage?) have a rounded end. In fact, It isn’t clear to me which models use which dimmer switches?

Example dimmer switch from the CJ-3A page forum.

So, here’s a look at Patterson’s switch. The first obvious difference is that the housing doesn’t have tabs. Instead, it has crimps and, let me tell you, those crimps wouldn’t bend easily outward.

Using a small screwdriver, I eventually got the crimps straightened. As soon as I tugged at the top part to remove it, everything kind of tumbled onto the table (oops).

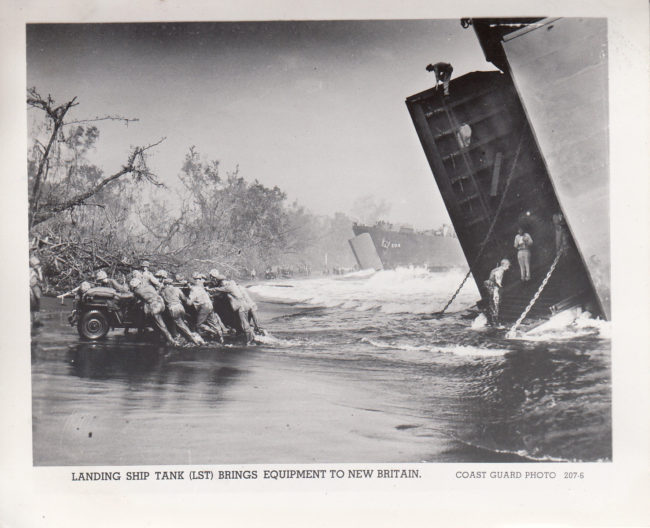

Using the fording kit, a jeep could operate for more than 15 minutes while under a foot or more of water. It was published in the January 1947 issue of Popular Mechanics.

This December 1943 article from Popular Mechanics highlighted an early attempt at a water proof jeep. In this case it was accompanied by a waterproof trailer.

1. Looks like these Allstate hubs are in reasonable condition.

“Sears Locking hubs for most early jeeps. Show normal ware but work great. Includes bolts. Removed from 1953 CJ3A.”

2. These “heavy duty” Selectro units, which came out in the early 70s, could use some cleaning on the outside.

“Selectro 11024 Locking Hub GPW Jeep CJ CJ2A CJ3A CJ3B CJ5 M38 Willys 10 Spline”

Chris Mckay will be doing a fast road trip to Indiana starting Wednesday.

“If anyone needs something hauled like parts and/or vehicles let me know. I’ll be going to northern Indiana and Grand Rapids , MI. I’ll be in MN, WI, IA, IL, IN and MI and NW Ohio” (nscustoms@hotmail.com)

Based on the above info, I drew up a map of his route. I might not have it quite right….

This April 1944 article from Popular Mechanics explains how target jeeps work. The photo shows a slat grille MB sacrificed for the greater good.

These first four are from the Korea War:

These photos show the Minerva, an armored jeep-like vehicle. The famous MINERVA (built under license of land rover) not the nicest, but served for several years in the belgian army -this is an exceptional version (and very rare to find these days) of the recon group – it’s heavy plated and gunned – greetz

The Alaska Or Rust Crew and Chris McKay (https://www.facebook.com/groups/533087846854829/) are giving away a second $150 gift certificate for Kaiser Willys. The winner will be chosen at random.

To enter, simply add a comment to this post OR, if you have a Facebook Account, add a comment to the Alaska Or Rust Facebook post. In your comment, indicate the first jeep you owned or drove (either one). On Thursday, July 6th, at 5pm PST we’ll select the winner.

Please don’t enter twice. We’ll be going through the all the names and then using a random number generator to determine the winner.

Many thanks to Kaiser Willys for these certificates! #alaskaorurst #kaiserwillys #ewillys

UPDATE: Dan’s laid out a caravan schedule for next weekend’s Open House.

Subsitute caravan leader Dan “scramboleer” here. Just a reminder that the Willys America Open House and BBQ is just a few Saturdays away on July 8.

The 2017 Caravan basically takes the morning to drive from Millbrae (south of San Francisco), across the Golden Gate Bridge, and then out through western Wine Country to Cazadero where Willys America hosts an open house and BBQ.

Here are the details:

Begin route on Hwy 280 North.

Stop 1: 8:00 am – 8:15 am Trousdale Exit on northbound Highway 280. (This exit is in Millbrae, meet on the east side parking area after the off ramp). The exit is about 5 miles north of Hwy 92.

Follow 280 North. Take 19th Avenue north through San Francisco to the Golden Gate Bridge (Hwy 101).

Stop 2: 8:45 am – 9:15 am Golden Gate Bridge vista point. (Located on northeast side of bridge.) Great picture spot!

Continue Hwy 101 north to Petaluma. Exit west onto Lakeville Road., Stop at McDonald’s at the shopping center on Lakeville Rd.

Stop 3: 10:00 am-10:20 am McDonald’s parking lot in Petaluma. (Exit west on 116/Lakeville St. and look for McDonald’s)

Continue on North 101 and exit at Hwy 116 West (Gravenstein Hwy towards Guerneville). Follow Hwy 116 through Forestville, Monte Rio and turn North onto the Cazadero Hwy. Follow Cazadero Hwy until you see Willys America, 6152 Cazadero Highway Cazadero, CA 95421.

This jeep seems to be expecting to be deep in water.

“1950 Press Photo American Jeep with supplies for 1st Calvary Division

This is an original press photo. An American Jeep hits the beach in South Korea with supplies for the front lines. The U.S. 1st Cavalry Division smashed a 14-hour tank-led attack by the North Koreans,. Photo measures 9 x 7.25 inches. Photo is dated 07-23-1950.”

Maury shared these two great photos.

On Tuesday afternoon, Patterson sprang to life with it’s new transplant!

We started Tuesday morning working through the wiring. I asked Ann to rewire the low-beam/high-beam floor switch, since much of the fabric had fallen away. That led to rewiring more of the harness than expected, which in turn delayed messing with the engine.

Once I could focus on the engine, the first thing I did was swap distributers, as Patterson’s engine had newer internals (and I knew for sure it worked). When installed, I tried starting the engine a few times, but didn’t have success. So, I rotated the distributor wires 90 degrees. When that didn’t work, I rotated them another 90. When that didn’t work, I rotated them another 90. That’s when I got the engine to fire, but not run. At that point I began rotating it a few degrees, then cranking the engine, then rotating again, so I could get a feel for which position seemed to fire the best. But, after trying this a few times, we still didn’t get it to run.

At that point, Ann suggested we try different spark plugs. I’d forgotten I hadn’t installed the ones that had been on Patterson (still attached to the head). So, we pulled them, checked the gaps, then installed them in the “new” engine. We got it to fire again, but then, mysteriously, it stopped firing no matter where the distributer was located. That was puzzling. About that time, ann noticed some heat at the generator. I suspect the regular got stuck, causing the battery to discharge into the generator, creating heat (at least that’s what I determined later of after doing some reading). So, I pulled the battery cable and let the system cool.

Once it was cool, I rotated the distrbutor back to teh position where it had fired the best, then climbed into Patterson to start the jeep, simultaneously working the choke and gas pedal. Sure enough, Patterson just needed some physical presence in the driver’s seat, because he started right up. At that point, I climbed out and played with the distributor to locate the sweetest sounding spot. (see the video on Facebook … I can’t seem to make it appear on eWillys … it lacks a muffler, so it’s a little noisy).

So, Patterson runs again. But, we discovered the temp gauge and oil gauges are not working, so those will need some attention. Unfortunately, we had to return to Pasco last night, because Ann has a doc appointment Wednesday. I accompanied her back to Pasco, as I have some updating to do to the website and need to organize the sale of some Alaska Or Rust t-shirts. More on that Thursday morning. We plan to be back in Renton early next week. My mother has knee surgery scheduled for the 5th, so we need to be around to help out.

Now, if only it sounded like a jeep. It seems the timing it off, so I’ll be working my way through that Tuesday morning. One fun fact I didn’t know … there’s no top center on an L-head. I wished I’d known that BEFORE I assembled everything. I didn’t check to see whether my flywheel has the flywheel marks.

Anyway, Patterson is all assembled. We only had one oil leak, but that was only because someone forgot to tighten the inlet line at the block. We also had a minor gas leak at the carb, but that was a trivial issue. Some plumbers tape solved that.

So, now I believe it’s down’ to timing. For those looking for a good resource on L-head timing strategies, this thread on the CJ-2A page is helpful: https://www.thecj2apage.com/forums/l134-ignition-timing_topic13819.html. The also may be helpful: http://www.cj-2a.com/techtips/timing/howto/l134-timing.pdf

Here are a few pics from the day:

Ann also produced some seat covers that have pockets at the front for things like a phone or wallet.

The grille installed.

Dave’s got these for sale.

https://minneapolis.craigslist.org/ank/pts/6192978257.html

2. “New in box. Ring and pinion sets. Spicer model 27. One set is 3.31 other is 4.88 will ship”

My wife spent her second-birthday helping me in the garage (The 25th of June is the day of her bombing .. she says it was like a whole new life after that). She’s a great help; she does any task asked without complaint. I couldn’t ask for a better co-mechanic!

It’s late, so I’ll make this short. We made good progress today. We installed the vacuum holding tank, installed the passenger seat, bled the brakes, rewired some of the frayed wires, connected the transmission and engine, and slid the power train back into place. Now we just have to re attached some wires, hoses, and tighten a few things and we’ll get to test it. Here are a few

pics:

A couple things confused me today. In this first example, we have at top the original gasket between the intake manifold and carb. On the bottom is the replacement gasket included in a rebuild kit. As you can see, it won’t work. Is the DJ-3A intake that unique? I know it uses a Carter YF 2392, so that’s unique.

Next up, the ends for the dragline. On the left is the new end and on the right the old one. The new one is taller and has shallower slots for installing it. The old end is shorter and has much deeper slots (those deeper slots are really helpful) . Anyone know why these are so different? Between the longer end and longer springs, I couldn’t put all the parts together around the bell crank arm (and I tried). In the end I was forced to use some old and some new parts.

Note the difference in the spring heights. Try as I might, I could not compress the spring enough to install an end. I changed to the old end.

Once I used some of the old parts, I was able to get the draglink installed.

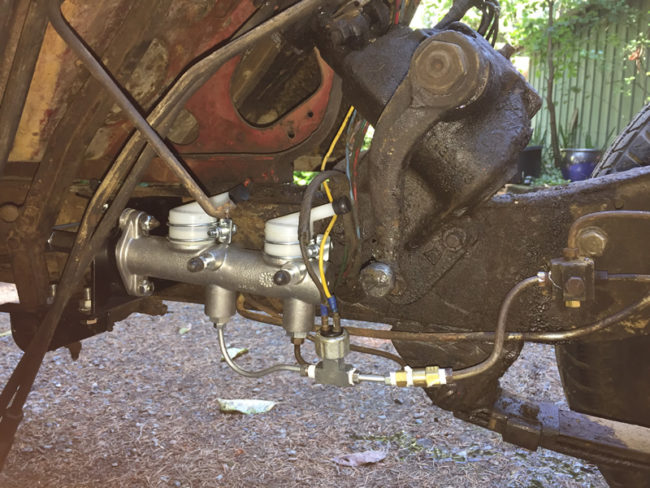

I also installed the dual master cylinder. The rear brake line connected perfectly. I just had to add one bend. The front brake lines were a big problem. You’d think trying to locate an 3/16-1/4 adapter would be easy, but it turned into multiple trips to the auto store, where I hunted for the right sizes with the right threads. The staffs at two different auto stores were not useful (nice, but not helpful). So, this will work for now, but I’d like to get the proper adapter and remove the connectors and line on the right side.

Sunday morning we’ll 1) bleed the brakes and then, if all goes well with that, 2) replace the front springs and then 3) drop in the engine.

There must be a story with this photo.

“1940s WWII Photo from another unnamed US Army soldiers photo album. Most appear to be at a unknown California army base before heading to the Pacific Theater of Operation. Nothing written on backs nor in album so no other info available.”