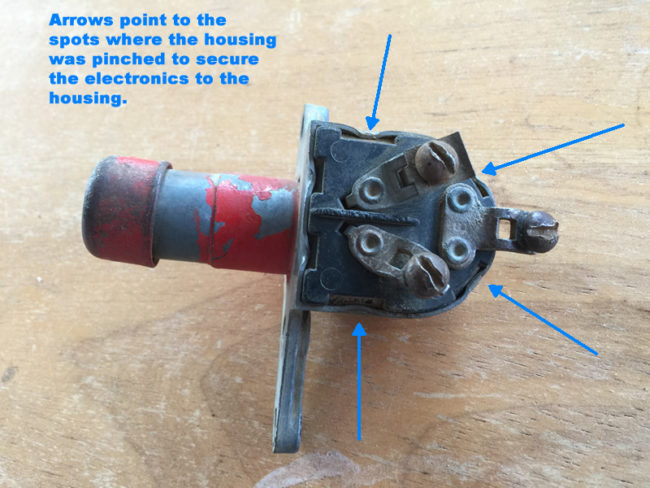

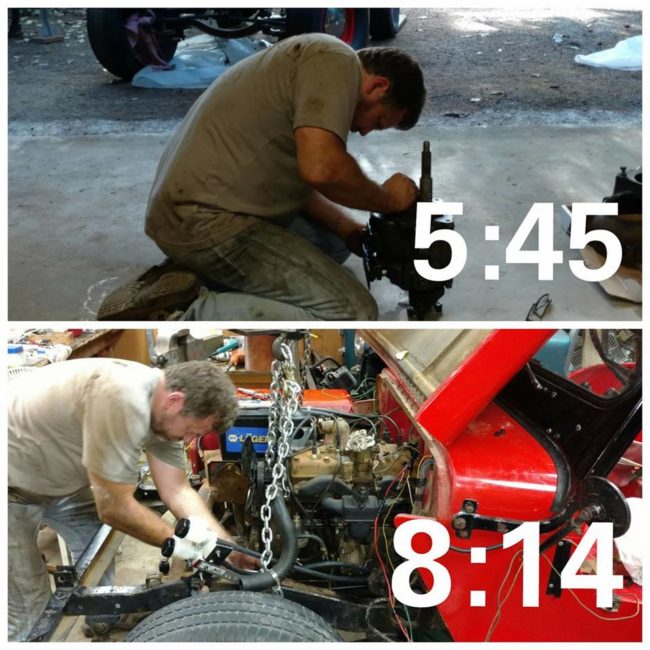

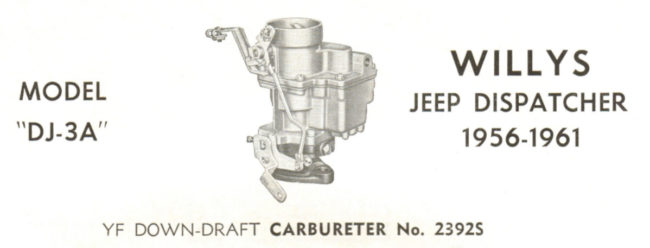

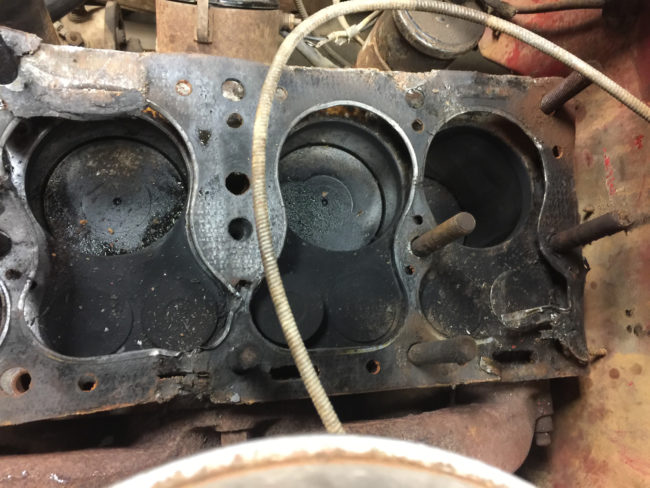

I spent Saturday and part of Sunday working through some fuel system issues. What I thought was a bad fuel pump (I spent a short time on it this spring) seems to have been some kind of blockage in the line. So, I drained the tank (the updated stainless rear tank has a drain at the bottom), blew the line, then refilled with new gas and, viola, it ran. I think it just sat too long at mom and dad’s. I also replaced the old generator (which didn’t work) with one given to me by Joe-in-Mesa during our Feb visit. So far, it seems to be working.

Below is a short video clip. So, that makes 2 of 4 jeeps running! That’s progress!

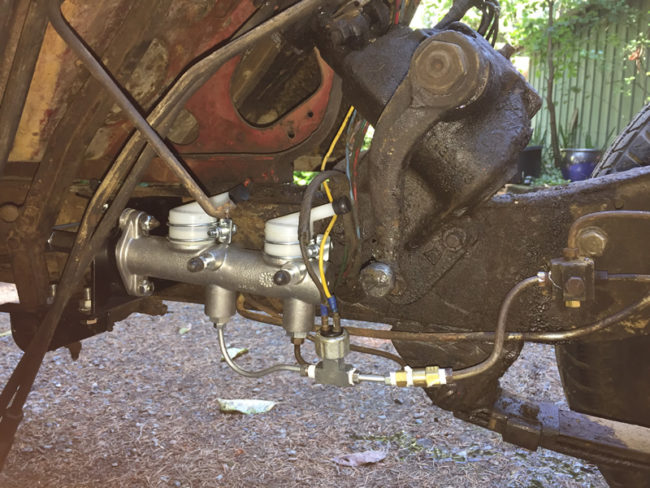

The downside for me with this jeep is that I don’t fit in it well (too long of legs). it could also use an alignment. Finally, I wish the brakes stopped a little better, but that’s not a priority at the moment.

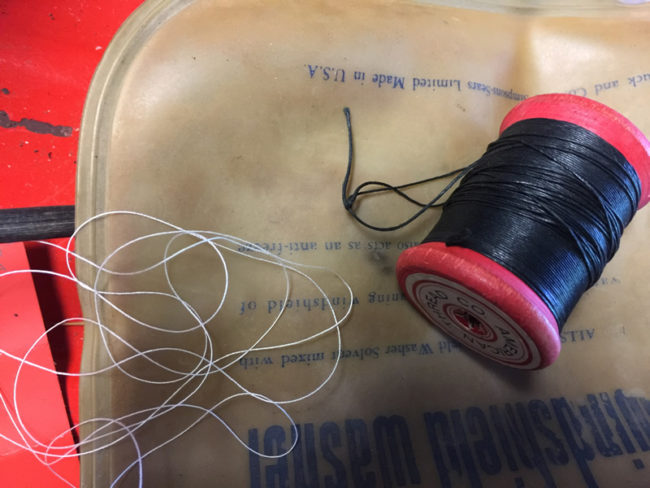

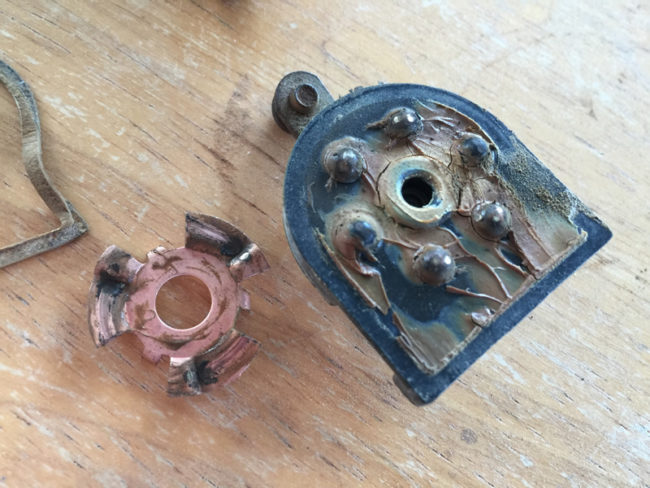

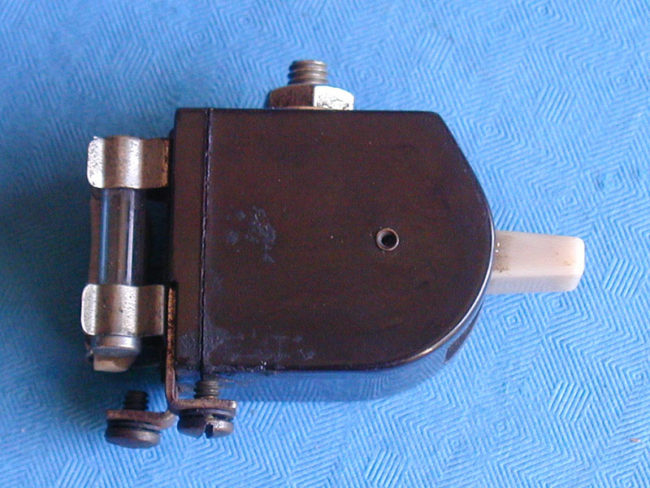

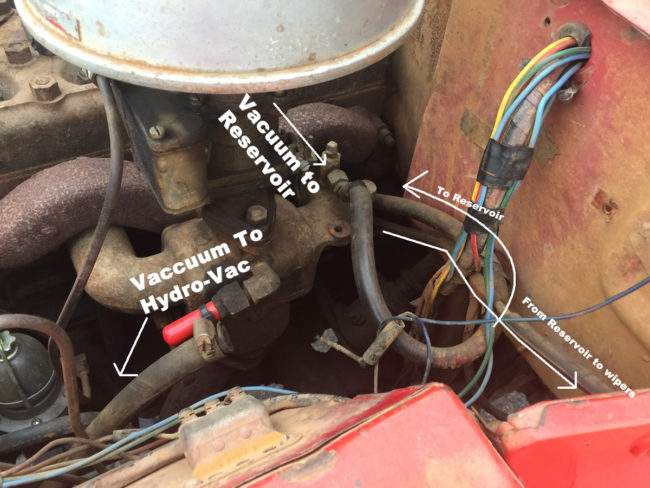

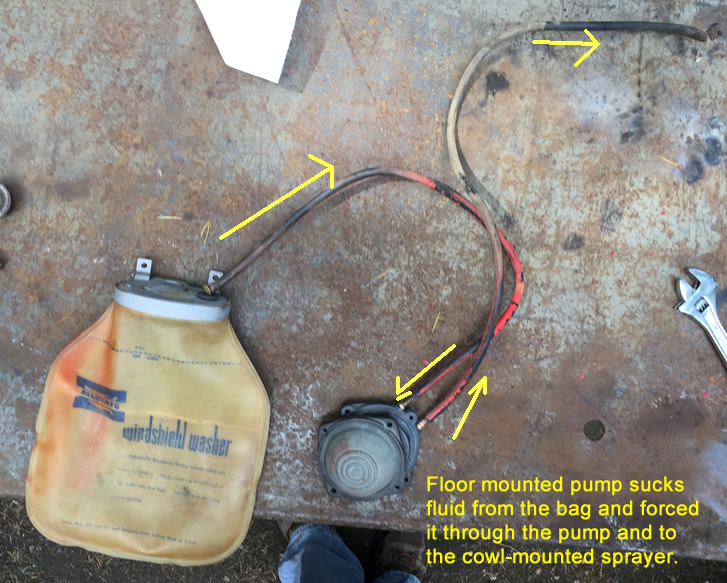

The body is rust free. You can drive it as is or repaint and restore it. The jeep includes a very rare Allstate window wash spray system and an equally rare Vacuum tank that adds power for operating the windshield wipers (one is missing a blade .. I haven’t needed to use them).

Being a convertible model, it has the original windshield with twist knobs across the top. I have nearly all the convertible top parts that attached to the body. The convertible loop only has the main bar, not the secondary bar that leaned off the back of the main bar. There is not soft top either.

The tow setup includes a towbar (not shown) that connects to a bracket mounted on the front bumper that uses stock holes, so the bumper remains unmolested.

So, if someone wants to buy this from me for $8000, contact me at d @ deilers.com.

I’ll throw in this three axle trailer for another $8000. I bought it along with the FC Tour jeep, but I think this trailer with just be sitting around and not used much. Since we already have a tilt trailer that can handle the FC, I don’t really need this one. I can take more pics or supply more info if anyone is interested. We towed it from Arizona and, once we got the wiring sorted out, it worked great for us.