UPDATE: Still Available.

(02/18/2024) Unclear if the doors aren’t installed or missing entirely.

https://www.facebook.com/marketplace/item/216369894835139

“1958 Willys Run good. It had a restoration many years ago. Possible trade. Pm. For details”

UPDATE: Still Available.

(02/18/2024) Unclear if the doors aren’t installed or missing entirely.

https://www.facebook.com/marketplace/item/216369894835139

“1958 Willys Run good. It had a restoration many years ago. Possible trade. Pm. For details”

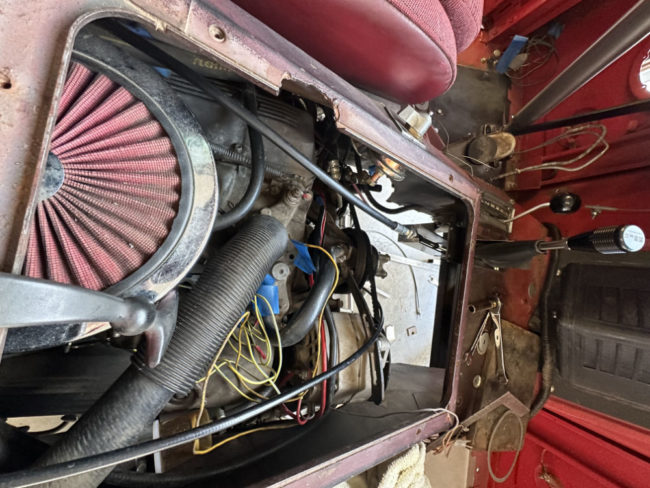

This Commando has an unusual dash setup.

https://www.facebook.com/marketplace/item/1230976524956311

“It has a Buick 350 swapped into it, which runs surprisingly well. It has never failed to start, even after sitting for years at a time. It runs and drives, but needs steering attention and brakes redone. Body is in overall, decent shape. Top is in rough shape and is only on to protect from the elements. It has an original dash, and dash pad, along with a new steering column. There is no wiring, other than what is necessary to start the vehicle. It will come with a new wiring harness, from “Painless Performance”.”

One is very rough.

https://www.facebook.com/marketplace/item/2010414802675783/

“Up for sale is TWO 1960ish AMC Mighty Mite Jeeps I believe they are 422A1 models neither have the correct engine transmissions radiators etc. but there are a lot of usable parts for someone’s restoration project I am asking $5000 for both. Or best offer. No titles. Just a bill of sale they are located in Tooele, Utah. About 30 miles west of Salt Lake City, Utah I would trade for some 106 RR parts, M220 Tow missile sights or parts or some M274 A5 parts to finish my other restoration projects please either messenger me or text me @ 801 232 2322”

UPDATE: Still Available. The seller relisted this under a new link, so maybe contact will be easier? See Mike’s comment below about contacting the seller.

This may have compression issues.

https://www.facebook.com/marketplace/item/725860106346720

“Runs but has low comperssion on 2 cylinders”

Has some body rot. Gas tank is in the rear bed.

https://www.facebook.com/marketplace/item/1462389428031235

“1948 Willy’s jeep has been sitting for awhile engine turns over. $3500 or best offer”

Unclear how much value is here.

https://www.facebook.com/marketplace/item/441127548399979

“Listing my 46 jeep cj2a or 3a plaque is faded. It has a manual transmission and a 351 ford v8 in it. Bought it to build into an off-road rig but haven’t touched it in almost 6 months. It’s a project has rust/rot frames good. front axle is missing pinion and ring gear and has been missing since i got it. was going to 4 link it and put it on one tons. steering wheel needs to be fixed, needs gas tank engine has new coil and distributor runs on starting fluid or gas dumped down the carb. could use a fresh rewire job solid bones just lost interest and don’t want it sitting around. Asking $1200 obo worst i can say is no have tractor to help load on a trailer tires are dry rotted hold air for about a day. It’s a good start to a off road rig”

The 2A body is atop a YJ chassis.

https://www.facebook.com/marketplace/item/2370441436495299

“1946 Willy’s on a YJ chassis. 4 cylinder 2.5 5 speed manual 4×4 It has a Clean GA title This a definitely a project but it will still crank up and drive . Open to trades for other vehicles especially if they have manual transmissions / or are classics”

UPDATE: Still Available.

(04/05/2024) This has a spring-over-lift with a modified steering setup (see last pic).

https://www.facebook.com/marketplace/item/793246858897357

“$4,000.00 must pick up in Cheyenne, WY. No title, ran a couple years ago.”

The rear doors look in good shape. Thanks to John for sharing it.

https://www.facebook.com/marketplace/item/967923331361281/

“1960 Willys jeep panel wagon just the body and nose. No frame, would make a nice rat rod or yard art or whatever. Drop an S10 frame under it and you’re good to go. It’s in decent shape for what it is located Chelmsford mass. Sold with just a bill of sale lol”

This FC-150 just sold for $25,000 at a Bring A Trailer auction. Lots of good interior photos.

https://bringatrailer.com/listing/1961-willys-fc-150/

“This 1961 Willys Jeep FC-150 has been refinished in green and yellow and features a front winch, dual side mirrors, and a drop-down tailgate. The truck is powered by a 134ci Hurricane inline-four linked to a three-speed manual transmission and a dual-range transfer case. Further details include a side-mounted spare tire, a cab heater, locking front hubs, and vinyl seating surfaces that match the exterior color scheme. It was acquired by the seller in 2018, and subsequent work included performing fluid services and replacing ignition components. This FC-150 is now offered with a bed cover and transferrable New York registration in the seller’s name.”

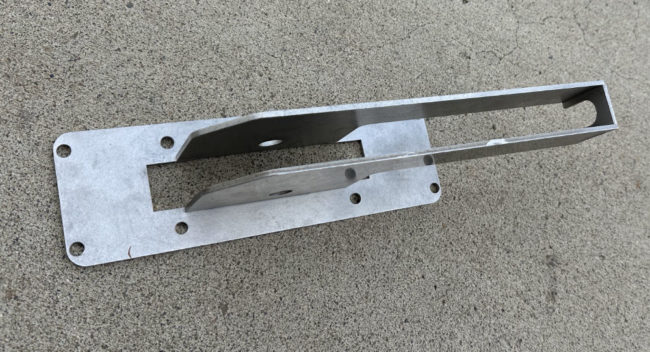

Now that I have the longer, six foot cable, I had a chance to continue with the transfer case shifter. The bracket that was provided by JB Customs, caused the shifter cable to run into the engine, which didn’t seem like a valid strategy, so I roughly calculated the angle, then made two cuts into the aluminum bracket. This allowed me to re-mount the bracket and then bend the bracket into the right position, but maintain the correct bracket-end distance.

Here are two pics of the original bracket:

This pic shows one of the two cuts plus the new angle. Even with that small bit of metal holding up the bracket, the shifter could easily shift through the gears. So, next I’ll repair that gap.

Here you can see how the cable angles upward, the veers toward the driver’s side. I haven’t determined where I’ll be securing the cable.

The shift boot needs to be reattached under the bezel. The bezel is the original bezel with the colorful surface sanded, which turned out to be exactly what I wanted. I’ve painted it red since this pic was taken.

The shift boot needs to be reattached under the bezel. The bezel is the original bezel with the colorful surface sanded, which turned out to be exactly what I wanted. I’ve painted it red since this pic was taken.

Here’s the shifter all the way forward. It’s surprisingly (to me anyway) easy to shift.

Next up I was going to build the final parts for the transmission oil cooler and fan bracket, but I have misplaced a couple pieces that I created and now can’t find them. So, I’ll work on the 1.5″ gauges next. Then, the gas pedal.

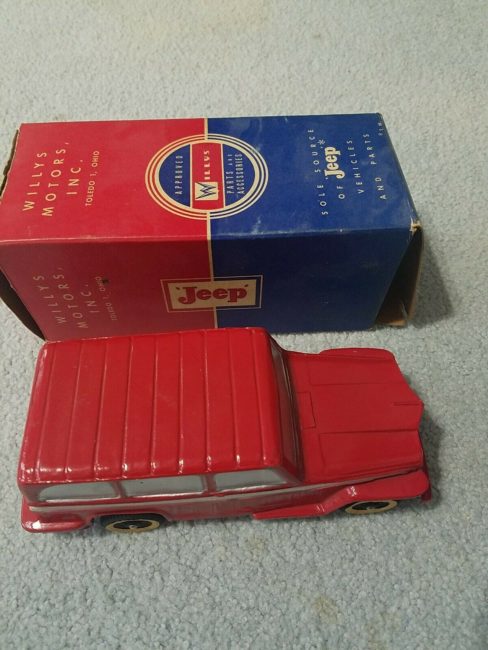

This rare model of an early 1960s Willys Wagon by Authenticast just sold on eBay for $184.45.

More pics of the blue one in a moment. In 2022 there was a red version for sale with an asking price of $425. I don’t know what became of that one. You can see pics at the bottom of this post.

Now, back to the blue one.

Listed as a 1952, it’s not clear if this is actually a 3A or a CJ-3B chassis (or something else). The body looks to be a very rare Parkette CJ-3B body kit.

https://www.jeepwillysforsale.com/1952-jeep-cj3b-w-turbo-400-in-la-pine-or/

“Cj3b, high hood, 350 chev. Holly hi rise, weber carb, accel hei, turbo 400, b&m, cj5 running gear, everything underneath is rebuilt

Painless wire kit, best top safari top in great shape, l have a brand new extra passenger door, new seats moved back4″,tilt steering, all gauges work, 12 gallon gas tank, new warn hubs, new rear driveline, never wheeled, stored inside

I have driven from Prineville to Portland numerous times. $11000. The only trade would be a very nice Dual Sport.”

Looks promising.

https://www.facebook.com/marketplace/item/1617990472361425

“Almost all original, body off restoration no rust,”

Only the one pic provided.

https://www.facebook.com/marketplace/item/438434008557071

“55 willies New rebuilt F head New clutch, bearings, brakes,tires. Road,trail ready.9k”

UPDATE: Price dropped to $10,500.

(03/21/2024) This jeep was built from a galvanized body and has a fiberglass Bobcat hood.

https://www.facebook.com/marketplace/item/1824739484614901

“1955 flat fender

Galvanized Philippines flat fender body

Scout frame and axles

4:10 gears welded front and rear

351W balanced

.030 over flat top pistons

Ported heads roller rockers

Not sure specs on cam

Gear drive

Holley 750

Top loader ford 4spd

20 t-case

New seats

Keep doesn’t have a lot of miles on it since it was put together”

Looks like a solid rig.

https://www.facebook.com/marketplace/item/2583428838495147/

“Very nice 1946 Willys CJ-2A for sale. Mechanically VERY sound. Motor completely rebuilt 2,100 miles ago. Runs quiet, cool and very strongly. Zero knocks or pings. Locking hubs in great shape. Recent brake work done. I would drive this jeep anywhere (and often do).

Tires in excellent condition. Spare has never seen the road. Bestop top and doors included. Mirrors, seatbelts and brake lights/turn signals added.

At some point, a previous owner converted the windshield to a single pane and added electric wipers. Judging by the wiper mechanism this was done a long time ago. I have most of the hardware (not the inner frame) to convert back to the spilt windshields. Could easily be restored from parts available here for not a ton of money.

Many spare/extra parts/repair and service manuals included.”

Craig’s got this project for sale.

https://www.facebook.com/marketplace/item/1358004398196354

“1946 Willys CJ-2A Jeep…$6500…CJ-2A chassis…WW2 MB motor and body…Frame is done, new paint, springs, shocks, brakes (need to be bled)…Body very solid, needs to be finished/paint…Needs wiring finished…Current Vt. registration…Sold with Bill of sale and registration signed to buyer….Randolph, Vermont 80two-728-968two.”

UPDATE: **SOLD** Was $3500.

I believe this is another of Andy’s former MBs.

“For your consideration, a nice example of a restorable 1945 Willy MB. All original tub, floors, And engine. Period Correct engine and trans both rebuildable. Bill of sale only”

Unclear how much value is here, but it runs.

https://www.facebook.com/marketplace/item/472024488488890

“project with lots of potential. Runs and drives but should be towed to location. Engine is not original, it is a Chevy 4 cylinder.  I got this rig from a friend who has the title, if we can’t locate the title I can get an affidavit”

TJ shared this truck. The body might be in decent shape.

https://www.facebook.com/marketplace/item/898126975335414

“Willys PU no engine have trans with small block chevy pilot shaft. AS IS.”

John shared what looks to be a DJ-3A body on a CJ-3A chassis.

https://www.facebook.com/marketplace/item/941815087396955/

“Selling this amazing non running survivor A CJ 3 with original unmolested drivetrain Engine turns with a wrench Gears move freely Brand new frame!! Tub in poor condition , but fixable No title or tags But everything can be done( I ll Tell you how I did my CJ 2!)”

Project or parts.

https://www.facebook.com/marketplace/item/448023564276949

“Flat fender jeep project, clean oregon title, complete aside from engine and transmission, roll cage, diamond plate corner armor and steps. Open to trades let me know what you have.”

Here’s an odd, but hardly looking project.

https://www.facebook.com/marketplace/item/625566673088155

“Nice older Jeep project 4×4 works has a 6 cylinder engine with manual transmission, needs work on the brakes, new battery, tune up, you must bring a trailer, you cannot drive it home, dump body works, come use it for hauling wood.”

Mike’s selling his nicely restored M-38A1. It’s currently on display at the Camp Gordon Johnston Museum in Carrabelle, FL. You can contact Mike via email jweiksner2 @ comcast.net (remove spaces from around the @) or via phone 706 832 3721.

“The M38-A1 is in excellent condition, is fully restored and runs great, US Army color and decor.

All original including seats,

F-134, 4-cylinder engine

Complete set of OEM operation and maintenance manuals,

Lots of spare parts including side covers, rear antenna, fire extinguisher, blackout lights, etc.

Clear title & BOS.

Location of the Jeep is in Carrabelle, FL, 32322, Carrabelle is directly south of Tallahassee about 1 ½ hours.”