UPDATE II: Some additional photos of the Esslingen, Germany, recondition facility posted to Facebook. The first one is similar to the final photo in this post, but the details show it’s a different photo (probably earlier given these have soft tops and military markings.

UPDATE: This was originally published in 2013.

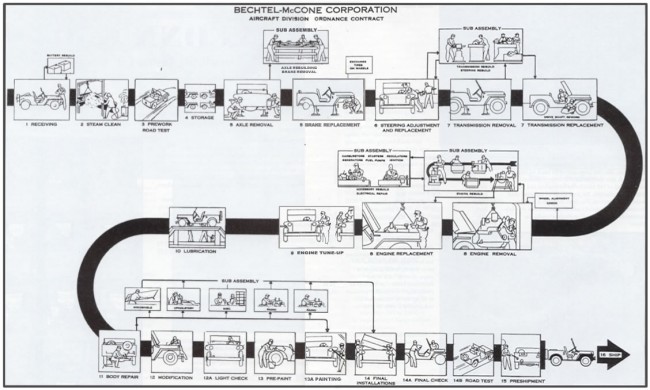

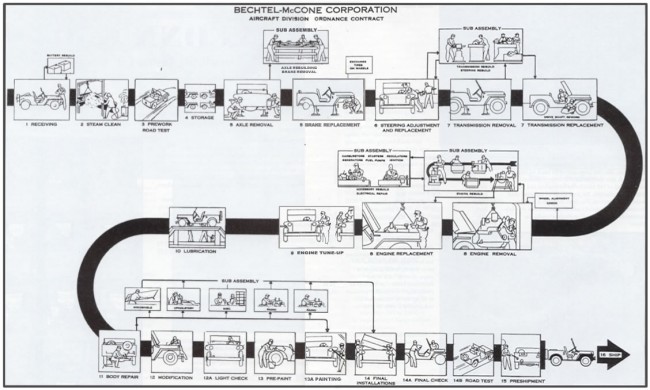

The Bechtel-McCone Remanufacturing Process rebuilt from an article in issue #122 of the Army Motors Magazine Winter ’08 by Lloyd White

One topic that appears in my new book is the 1941 attack on Russia by Hitler. Called operation Barbarossa and named for the medieval Holy Roman Emperor Frederick Barbarossa it was the largest invasion in the history of warfare. It included three million soldiers, 600,000 vehicles, and 750,000 horses. For comparison, the D-Day invasion force was approximately 150,000 men. Even a month later, only a million men had landed on the beaches of Normandy.

Supporting these huge numbers required plenty of logistics. For example, the German military had 250 companies of veterinarians that, at the height of the war, were capable of servicing almost 100,000 horses a day. Near the end of the war, horses became vital for the Germans on the Eastern front, as the terrain was often too inhospitable for vehicles, if they had any running vehicles at all.

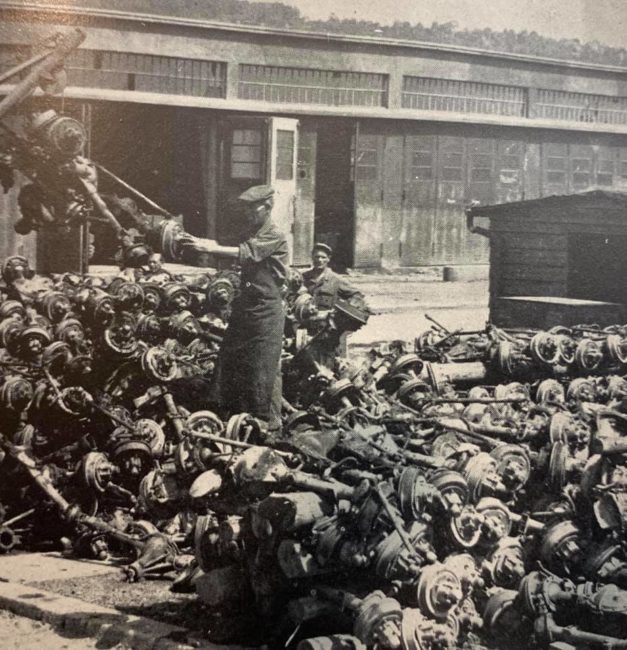

What does this have to do with jeeps? Well, despite their disposable nature, many people don’t know that the U.S. Army’s Ordnance Department created special facilities to rebuild jeeps (and other vehicles). Facilities were located both in the U.S. and abroad. Here’s some information about the US divisions.

I spent time last night, probably too much, gathering and organizing some information about these programs. The idea and much of this information came from Maury Hurt’s efforts to gather and document reconditioning programs. There are a variety of threads about these at G503. However, what I didn’t see was a place that gathered the information together as I have below. I expect to add to this post over time with more information about the international programs.

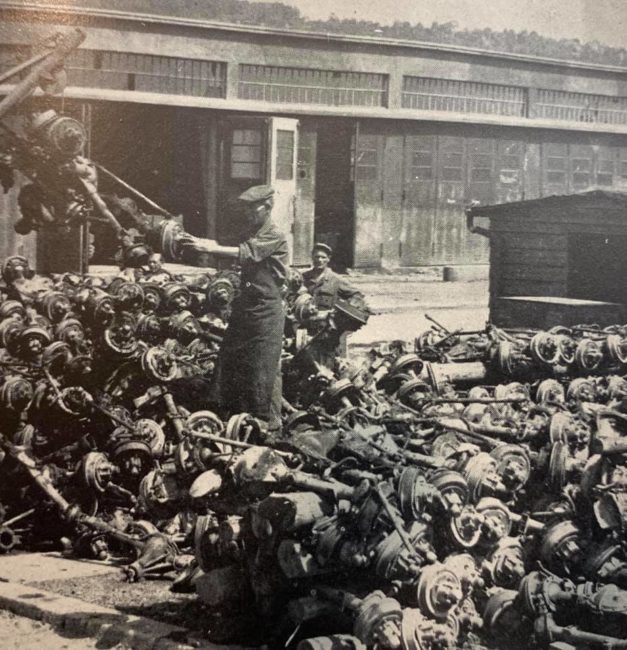

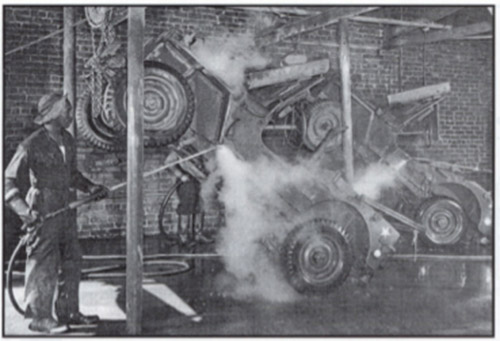

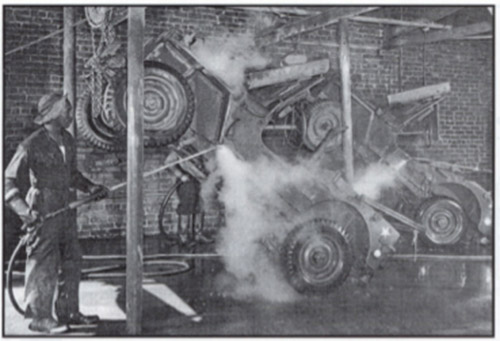

Steam cleaning jeeps at Bechtel-McCone’s remanufacturing facility in Birmingham, Alabama.

UNITED STATES REMANUFACTURING:

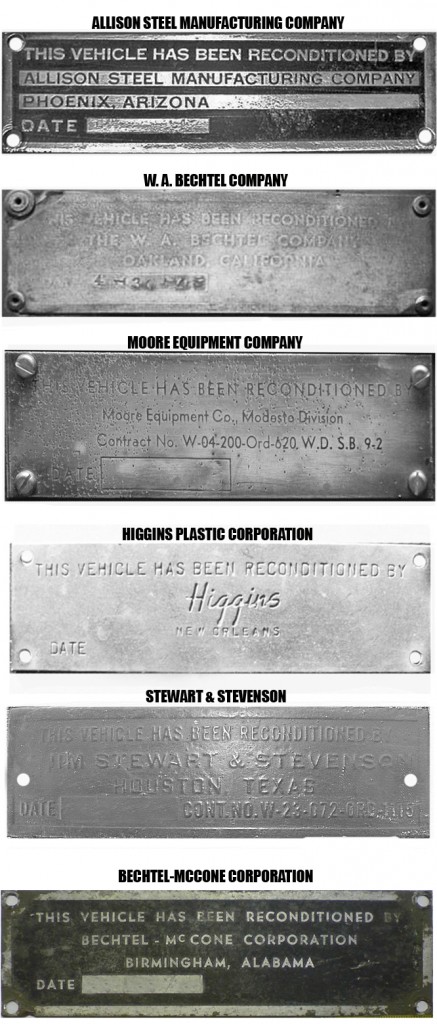

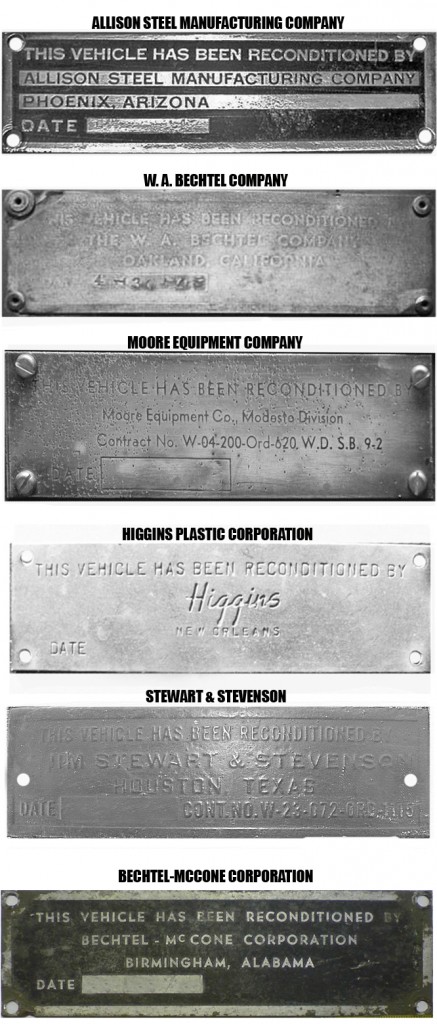

The following companies remanufactured a total of 16,176 jeeps in the United States according to Charlie Weaver via Jim Allen’s book “Jeep”. There are examples of the data plates applied to the dash of jeeps by the companies below. Unfortunately, I couldn’t find examples for all the companies. Next to the companies are the number of jeeps each is credited with rebuilding.

1. Bechtel McCone 4,986

2. Allison Steel Manufacturing Company Plate 2,865

3. Moore Equipment Co plate and a second one and a third one. 2,443

4. Higgins Plastic Corp 1,850

5. Stewart & Stevenson 1,750

6. W.A. Bechtel plate 1,555

7. Bishop McCormick & Bishop (no examples found) 343

8. International Diesel (no examples found) 267

9. Vancura Motor Company (no examples found) 66

10. A.M. Meyerstein (no examples found) 49

I found these plates in several locations (documented in the links above) and then organized them as you see. I thought it would help people who run into plates, but don’t know what they have.

Continue reading →